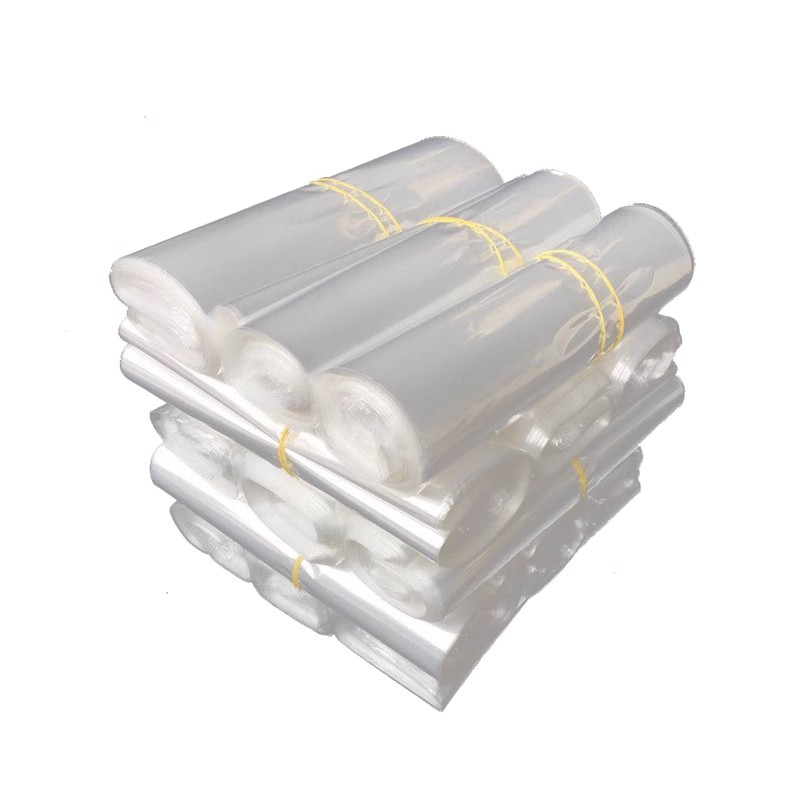

PE Shrink Film for Food Packaging

Certainly! Here is a formal and lengthy essay on the topic of PE Shrink Film for Food Packaging. Next, Xiamen Guanhua will introduce you:

Send Inquiry

The Versatility and Efficacy of PE Shrink Film in Food Packaging

In the dynamic landscape of modern food packaging, polyethylene (PE) shrink film has emerged as a versatile and highly effective solution, catering to the evolving needs of both producers and consumers. As the food industry continues to navigate the challenges of preserving freshness, enhancing visual appeal, and ensuring efficient distribution, the role of PE shrink film has become increasingly pivotal.

Polyethylene, a ubiquitous polymer derived from the polymerization of ethylene, has long been recognized for its remarkable properties, including strength, flexibility, and resistance to moisture and chemical agents. These inherent characteristics make it an ideal material for food packaging applications, where the preservation of product integrity and the extension of shelf life are of paramount importance.

The unique phenomenon of shrinking, which is a defining feature of PE shrink film, allows for the creation of a tight, form-fitting enclosure around the packaged product. This snug fit not only enhances the visual presentation of the item but also serves to protect it from external factors such as physical damage, atmospheric contamination, and the detrimental effects of light and oxygen exposure. By creating a barrier that isolates the contents from the external environment, PE shrink film effectively retards the deterioration of food products, extending their freshness and prolonging their usable lifespan.

Furthermore, the versatility of PE shrink film extends beyond its protective capabilities. The ability to precisely control the film's thickness, tensile strength, and shrinkage characteristics enables manufacturers to tailor the packaging to specific product requirements. This customization ensures that the film not only safeguards the contents but also adapts to the unique shapes, sizes, and handling needs of various food items, from delicate baked goods to robust frozen entrées.

The application of PE shrink film in the food packaging industry is further bolstered by its cost-effectiveness and ease of implementation. The manufacturing process for PE shrink film is relatively straightforward, leveraging well-established extrusion and orientation techniques to produce high-quality, consistent results. This streamlined production, coupled with the material's inherent durability and reusability, translates to cost savings for food producers, who can rely on a reliable and economical packaging solution.

Moreover, the environmental consciousness that has permeated various industries has also influenced the food packaging landscape. PE shrink film, being a thermoplastic material, can be readily recycled and repurposed, rendering it a more sustainable alternative to certain non-biodegradable packaging options. This eco-friendly attribute aligns with the growing consumer demand for environmentally responsible products, further enhancing the appeal of PE shrink film in the food packaging arena.

In conclusion, the widespread adoption of PE shrink film in the food packaging industry is a testament to its versatility, efficacy, and cost-effectiveness. As the demands for improved product preservation, enhanced visual appeal, and environmental sustainability continue to evolve, the role of PE shrink film will undoubtedly remain pivotal in meeting the needs of both food producers and discerning consumers. With its ability to adapt to diverse product requirements, maintain freshness, and minimize environmental impact, PE shrink film stands out as a leading packaging solution in the dynamic and ever-evolving world of food packaging.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी