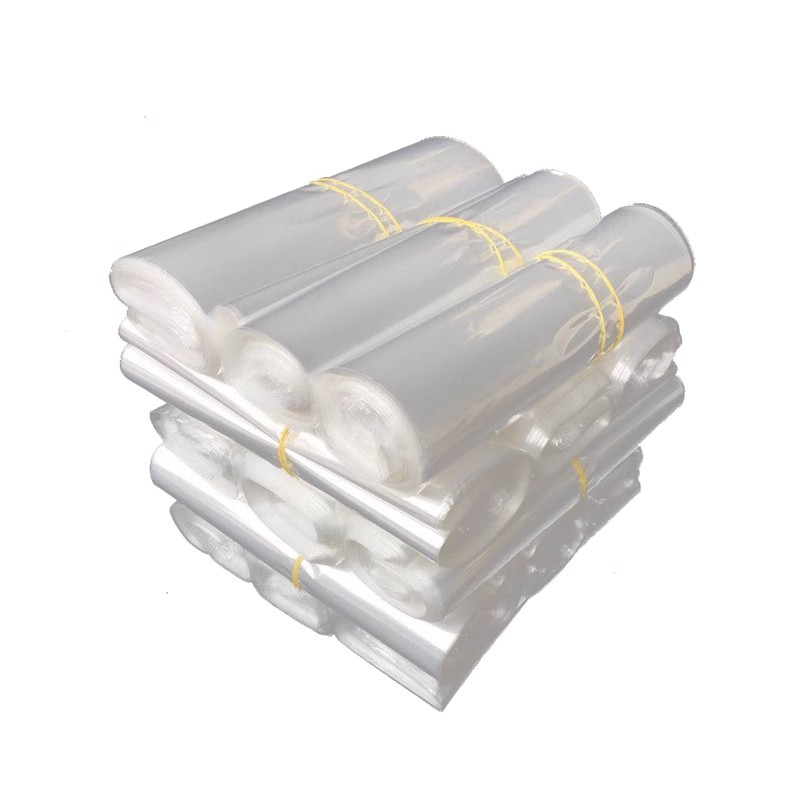

Cans PE Shrink Wrap

As one of professional manufacturers, Xiamen Guanhua would like to provide you high quality Cans PE Shrink Wrap. And we will offer you the best after-sale service and timely delivery. Our product is a good choice for you.

Send Inquiry

Xiamen Guanhua is one of leading China Cans PE Shrink Wrap manufacturers, suppliers and exporters. The three main wraps used in shrink packaging material for protecting and securing products for the retail and shipping environments are polyvinyl chloride (PVC), polyethylene (PE), and polyolefin (POF). Each has different capabilities and characteristics that make them suitable for specific applications.

Cans PE Shrink Wrap is a type of polyolefin, meaning it is a single monomer wrap that is formed with the addition of ethylene during polymerization. PE is used in several forms of flexible protective packaging including shrink wrap and stretch wrap and performs very differently for each.

There are multiple forms that PE can take, but the three most common would be Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), & High-Density Polyethylene (HDPE). Each of these is best used in different industrial applications, but for shrink packaging, LDPE would be the most common form.

The benefits of using Cans PE Shrink Wrap over the other forms of shrink packaging would be added strength and durability for heavier, larger items, like multipacks of beverages. These wraps are also printable and can have excellent graphics added while still maintaining the image and the strength required.

Where POF and PVC are limited in gauge thickness to usually around 100 gauge, higher gauges of PE are possible up to 1200 gauge! These thicknesses are used in Marine industrial applications, like shrink-wrapping a boat for storage. The disadvantages of PE for shrink are that it doesn't have a high shrink rate, usually around 20%, and it has significantly lower clarity than the other wraps.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी