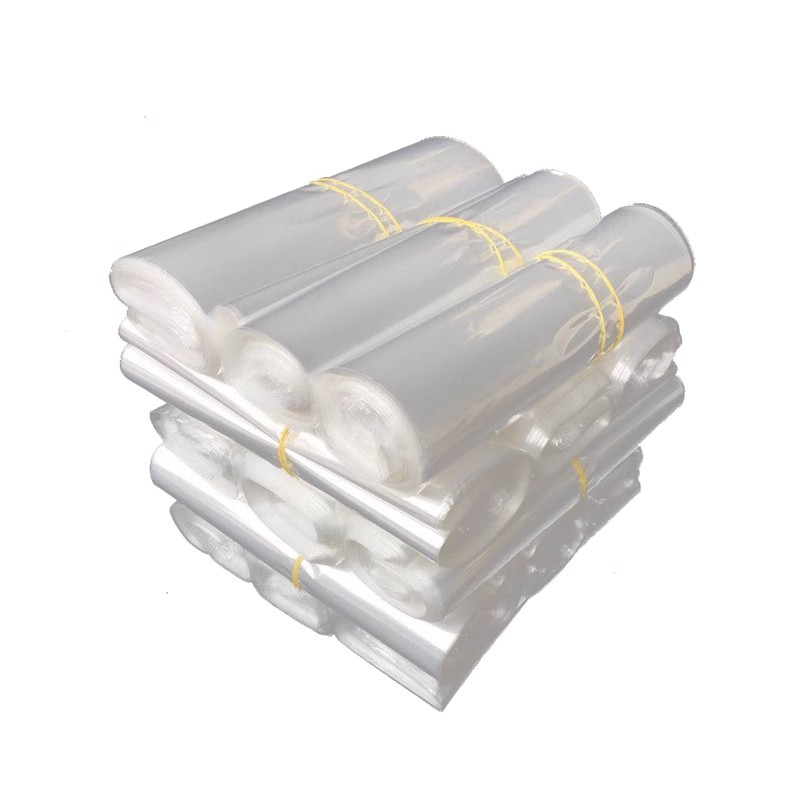

Low MOQ PET Shrink Wrap

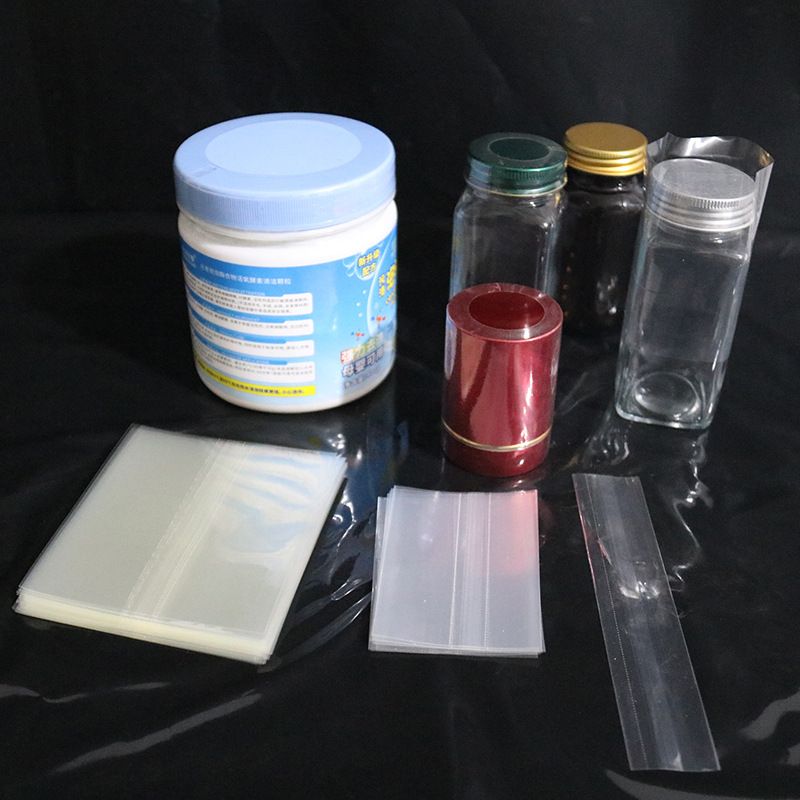

Xiamen Guanhua is a fully equipped factory and Low MOQ PET Shrink Wrap is one of our main products. Shrinkable polyester film is often used in convenient food and beverage markets, electronic appliances, metal products, especially shrink labels is its most important application field. Welcome to contact us!

Send Inquiry

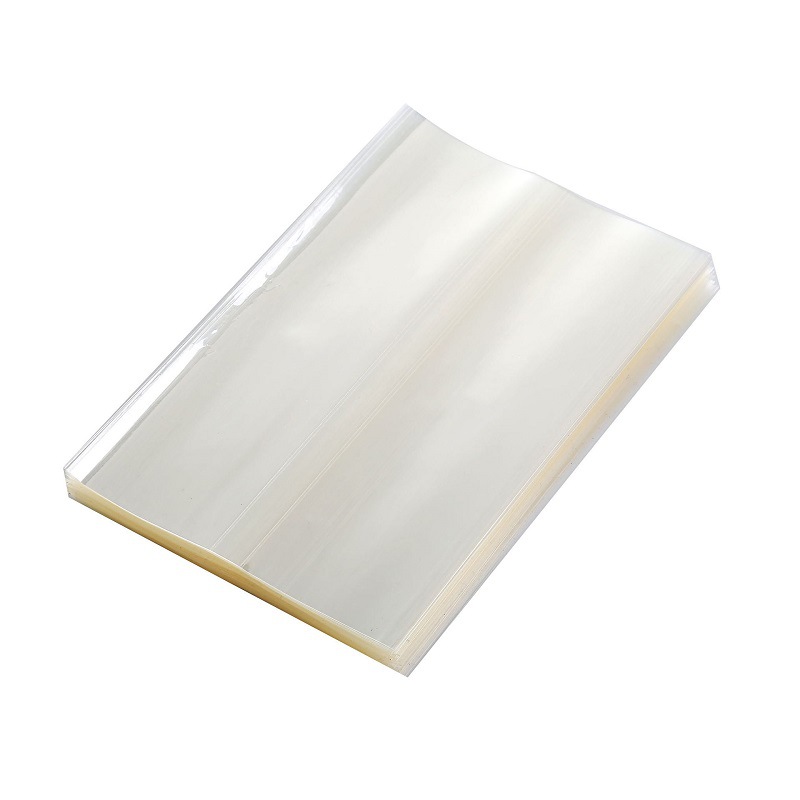

Low MOQ PET Shrink Wrap is a relatively comprehensive packaging film. Its transparency is good, shiny; It has good air tightness and fragrance preservation. They are produced by Xiamen Guanhua. The moisture resistance is moderate, and the moisture permeability decreases at low temperature. The mechanical properties of PET film are excellent, its strength and toughness are the best of all thermoplastics, and the tensile strength and impact strength are much higher than the general film; And good strength, stable size, suitable for printing, paper bags and other secondary processing. PET film also has excellent heat and cold resistance and good chemical resistance and oil resistance. But it is not resistant to strong alkali; It is easy to carry static electricity, and there is no appropriate anti-static method, so attention should be paid to the packaging of powdered items.

|

Product name |

|

|

Hardness |

Soft |

|

Usage |

Packaging Film |

|

OEM & ODM |

Acceptable |

|

Application |

Cosmetics, Drinks, Cleaning, Detergent, Skin Care Products, Hair Care Products, Oil, Dairy Products |

|

Samples |

Available |

|

Payment Term |

T/T, Paypal, L/C |

|

Origin |

China |

Low MOQ PET Shrink Wrap is combining high overall shrinkage and excellent printability.

The favorable film toughness and shrinkage character combine to make a film suitable for a wide variety of container shapes.

The film thickness is from 35-50mic, Shrinkage from 70-75%, Width upto 8.7m.

Providing full or partial body coverage, roll-sleeve films are formulated to work on roll-fed label machinery. So you get the superior graphics of shrink-label films and the high efficiency production of roll-fed labels.

Low MOQ PET Shrink Wrap:

1. Low shrink-initiation temperature requires minimal shrink tunnel length for energy savings & high-output line speed

2.Medium to high shrinkage properties

3.Simple & multiple contours, symmetrical shaped configurations allow for flexibility in container shape and design

4.Suitable for gravure, flexographic & rotary offset printing

5.Runs on existing printing equipment using conventional inks

6.Works with heat-bar, solvent, hot-melt adhesive & laser seaming

7.Use in steam or hot air shrink tunnels

8.Excellent processability during printing & shrinking (smooth flat seams)

9.No de-lamination

10.High-impact strength

11.Gloss/gloss surface finish

12.Clear, transparent film

13.Attractive total system cost due to high-speed labeling, low scrap rate, quick changeover, and wide-web printing

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी