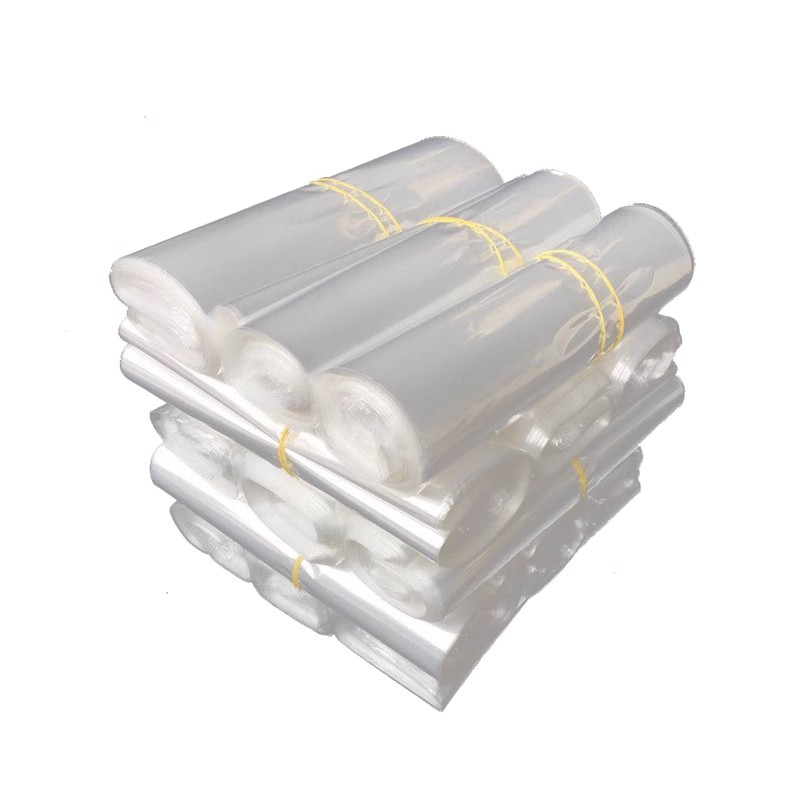

Cosmetic PET Shrink Wrap

Xiamen Guanhua is one of China Cosmetic PET Shrink Wrap manufacturers and suppliers. PET shrinkable film is a new kind of shrinkable packaging material. If you are interested in our products, please contact us.

Send Inquiry

China Supplier of Xiamen Guanhua is specialized in Cosmetic PET Shrink Wrap. PET film shrinkage refers to the use of specific temperature and time under the action of external heat, the process of reducing the size of PET film from large to small.

Cosmetic PET Shrink Wrap Theory:

is caused by external heating, resulting in fusion plastic deformation of the film under the action of force, each molecule of the membrane material randomly moves in a refractive trajectory, resulting in shrinkage deformation cheng.

The process of shrinkage deformation is influenced by temperature and time, that is, the longer the heating time, the more shrinkage the greater the degree. The lower the heating temperature, the smaller the degree of shrinkage, and vice versa, the higher the degree of shrinkage.

Cosmetic PET Shrink Wrap Process:

The prerequisite for PET film shrinkage is that the film material must have plastic properties. If the material does not possess plastic properties, the process of shrinkage deformation will be greatly affected. During the heating treatment process, changes in temperature can cause the movement of various molecules in the membrane material to be disrupted. The trajectory of the projectile constantly changes, resulting in changes in overall size.

Cosmetic PET Shrink Wrap Advantage:

PET film shrinkage has excellent properties such as transparency, heat resistance, and cold resistance, Not affected by temperature changes, with good chemical stability and heat resistance up to 250 ℃. It has good electrical insulation performance, sound insulation performance, and water penetration resistance due to the PET film. After heating, it will not produce smoke and dust, so it is a safe and healthy transparent film material.

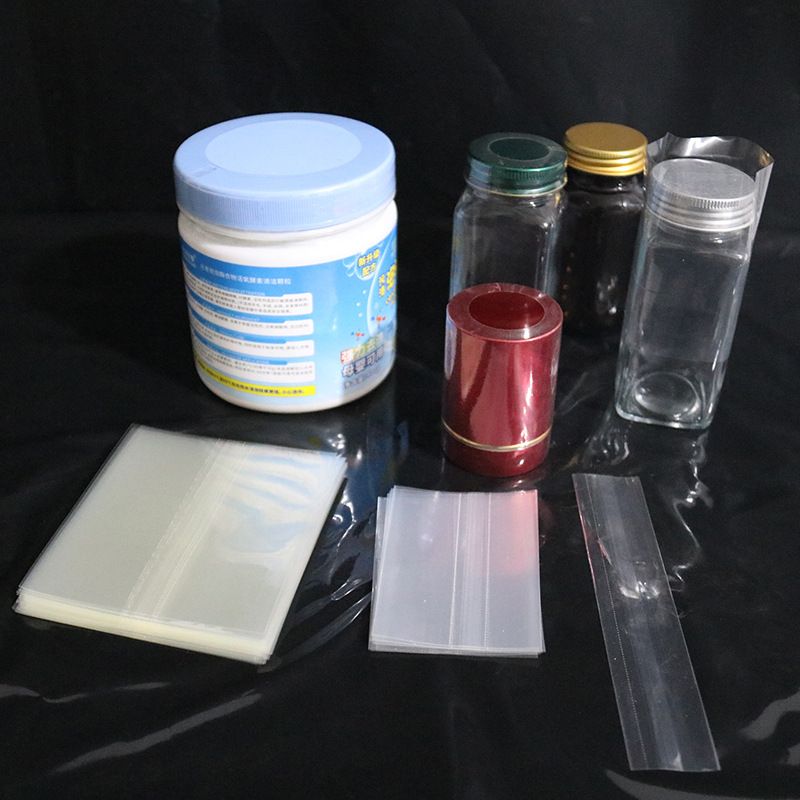

PET Shrink Wrap Application:

PET film shrinkage is widely used in fields such as food, clothing, medicine, cosmetics, etc

Used for the manufacturing of food preservation bags, packaging bags, and packaging liners. In addition, film shrinkage can also used in the clothing industry for shrinkage treatment of materials such as polyester fabrics and flannel. In medicine industry, can be used for manufacturing pharmaceutical bags and drug liners, as well as for manufacturing outer layers of drug boxes packaging.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी