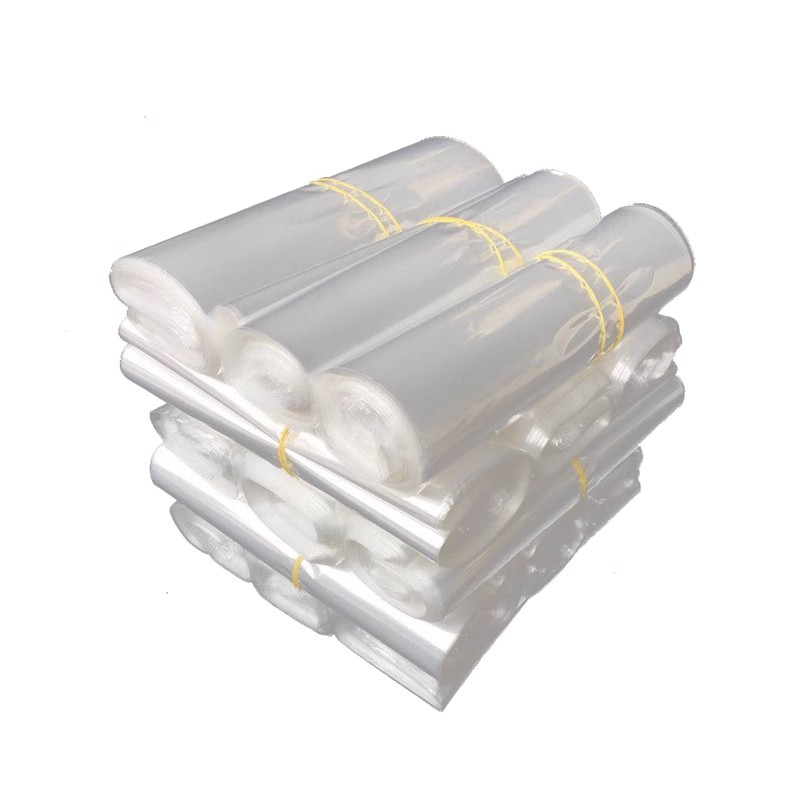

PVC Shrink Wrap Tubing

PVC Shrink Wrap Tubing is a Versatile and Resilient Packaging Solution. Xiamen Guanhua has a deep research on shrink packaging film, especially pvc shrink film, this product can accept customized size and shape, welcome to consult and order!

Send Inquiry

In the dynamic and ever-evolving landscape of modern packaging, PVC shrink wrap tubing has emerged as a versatile and indispensable solution. Polyvinyl chloride (PVC), a widely recognized and extensively utilized synthetic polymer, has found its way into various industries, with shrink wrap tubing being one of its most prominent applications. This essay delves into the intricacies of PVC shrink wrap tubing, exploring its characteristics, applications, and the multifaceted benefits it offers to industries across the spectrum.

PVC shrink wrap tubing is a unique and adaptive packaging material that undergoes a process of thermal shrinking to conform to the shape and size of the object it encases. This process, known as "shrink wrapping," involves the application of heat, which causes the PVC material to contract and tightly envelop the product, creating a secure and protective barrier. The versatility of PVC shrink wrap tubing lies in its ability to accommodate a wide range of products, from small electronics and medical devices to larger items such as furniture and industrial equipment.

One of the primary advantages of PVC shrink wrap tubing is its exceptional durability and resilience. The inherent strength and rigidity of PVC make it a highly resistant material, capable of withstanding the rigors of transportation, storage, and handling. This attribute ensures that the packaged products remain intact and protected throughout the supply chain, minimizing the risk of damage and ensuring the safe delivery of the goods to the end-user.

Furthermore, PVC shrink wrap tubing offers a remarkable degree of customization. Manufacturers can tailor the thickness, size, and color of the tubing to meet the specific requirements of their products, creating a seamless and visually appealing packaging solution. This flexibility allows companies to enhance their branding and product presentation, which can significantly impact consumer perception and purchasing decisions.

In addition to its physical properties, PVC shrink wrap tubing also boasts impressive environmental credentials. The material is highly recyclable, making it a sustainable choice for companies seeking to reduce their environmental footprint. Moreover, the efficient use of resources during the shrink wrapping process contributes to the overall sustainability of the packaging solution, as it minimizes waste and optimizes material utilization.

The versatility of PVC shrink wrap tubing extends beyond its packaging capabilities. It finds widespread application in various industries, ranging from electronics and pharmaceuticals to the automotive and construction sectors. In the electronics industry, for instance, PVC shrink wrap tubing is used to protect sensitive components and circuit boards, ensuring their safe transportation and storage. In the pharmaceutical industry, it is employed to create tamper-evident seals for medication packaging, enhancing product security and consumer safety.

The construction industry also leverages the advantages of PVC shrink wrap tubing, using it to protect building materials and equipment during transportation and on-site storage. The inherent moisture resistance and weatherproofing properties of the material make it an ideal choice for safeguarding construction materials from the elements, preventing damage and maintaining product integrity.

In conclusion, PVC shrink wrap tubing has emerged as a pivotal packaging solution, offering a compelling blend of versatility, durability, and environmental responsibility. Its ability to adapt to a wide range of products, coupled with its customizable features and resilient properties, has made it an indispensable tool in the packaging industry. As businesses continue to prioritize efficiency, cost-effectiveness, and sustainability, the demand for PVC shrink wrap tubing is poised to grow, solidifying its position as a crucial player in the ever-evolving landscape of modern packaging.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी