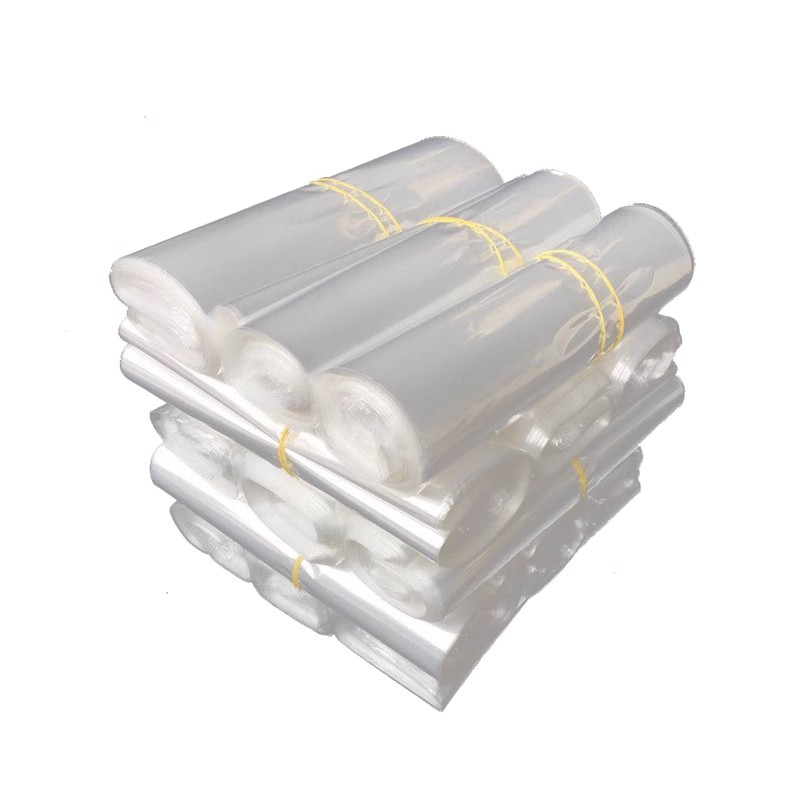

PVC Shrink Film

Certainly, I can assist you with that. Here is a formal and lengthy essay on the topic of PVC shrink film:

Send Inquiry

The Versatility and Utility of PVC Shrink Film

In the ever-evolving landscape of packaging and protective solutions, PVC (polyvinyl chloride) shrink film has emerged as a versatile and indispensable material. PVC shrink film, with its unique properties and diverse applications, has become a staple in various industries, contributing to the efficient and secure packaging of a wide range of products. This essay will delve into the intricacies of PVC shrink film, examining its composition, characteristics, and the multifaceted ways in which it has revolutionized the field of packaging.

At the outset, it is essential to understand the fundamental nature of PVC shrink film. Composed of a thermoplastic polymer, PVC shrink film is known for its remarkable ability to contract and cling tightly around an object when exposed to heat. This property, known as the "shrink effect," is a result of the film's molecular structure, which undergoes a transformation when subjected to elevated temperatures. As the film is heated, the polymer chains within the material realign and shrink, effectively creating a snug and secure enclosure around the packaged item.

One of the primary advantages of PVC shrink film lies in its exceptional durability and strength. The material's inherent resistance to tears, punctures, and abrasions makes it an ideal choice for protecting delicate or fragile goods during transportation and storage. This robust nature ensures that the contents of the package remain intact, shielded from the potential hazards of the supply chain. Additionally, PVC shrink film's ability to provide a tight, tamper-evident seal enhances the security of the packaged items, deterring unauthorized access and safeguarding the integrity of the products.

Furthermore, the versatility of PVC shrink film extends beyond its physical attributes. The film can be customized in a variety of dimensions, thicknesses, and colors to cater to the specific needs of different industries and applications. This adaptability allows manufacturers and distributors to optimize the packaging solutions for their unique products, ensuring a tailored fit and an aesthetically pleasing presentation. The availability of clear, opaque, and printed variants of PVC shrink film also enables businesses to incorporate branding, labeling, or informational elements directly into the packaging, enhancing the overall visual appeal and communication with the end-user.

The widespread adoption of PVC shrink film can be attributed to its exceptional performance characteristics, which have made it an indispensable component in numerous industries. In the food and beverage sector, PVC shrink film is extensively utilized to package a diverse range of products, from individual snacks and beverages to bulk items such as bottled water or canned goods. The film's ability to create a tight, protective seal helps to preserve the freshness, aroma, and flavor of the contents, while also preventing contamination and extending the shelf life of perishable items.

Beyond the food and beverage industry, PVC shrink film has found applications in a myriad of other sectors. In the pharmaceutical and medical industries, the film is employed to safeguard the sterility and integrity of sensitive products, such as medical devices, surgical equipment, and pharmaceutical packaging. The film's resistance to moisture, UV radiation, and other environmental factors ensures that the packaged items remain uncompromised during storage and distribution.

In the electronics and consumer goods industries, PVC shrink film plays a crucial role in protecting delicate and valuable items. From the packaging of electronics, appliances, and personal care products to the bundling of promotional items and gift sets, the film's ability to provide a secure and tamper-evident enclosure is highly sought after. The film's transparency also allows for the clear display of the packaged products, enhancing the overall visual appeal and consumer experience.

The environmental impact of PVC shrink film has also been a subject of ongoing discussion and research. While PVC has been the focus of some environmental concerns due to its chemical composition, the industry has made significant strides in developing more sustainable alternatives and improving the recyclability of PVC-based products. Manufacturers are now exploring the use of recycled PVC materials, as well as exploring the development of bio-based PVC derivatives, in an effort to reduce the environmental footprint of the packaging industry.

In conclusion, PVC shrink film has firmly established itself as a versatile and indispensable packaging solution, catering to the diverse needs of a wide range of industries. Its exceptional durability, adaptability, and performance characteristics have made it a go-to choice for safeguarding and enhancing the presentation of a myriad of products. As the packaging industry continues to evolve, the role of PVC shrink film is poised to remain crucial, driving innovation and ensuring the efficient and secure transportation and storage of goods across the global supply chain.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी