Heat Shrink Wrap Packaging

As one of professional manufacturers in China, Xiamen Guanhua would like to give you Heat Shrink Wrap Packaging. Heat Shrink Wrap Packaging is one of our main products. We can provide free samples, welcome to consult us!

Send Inquiry

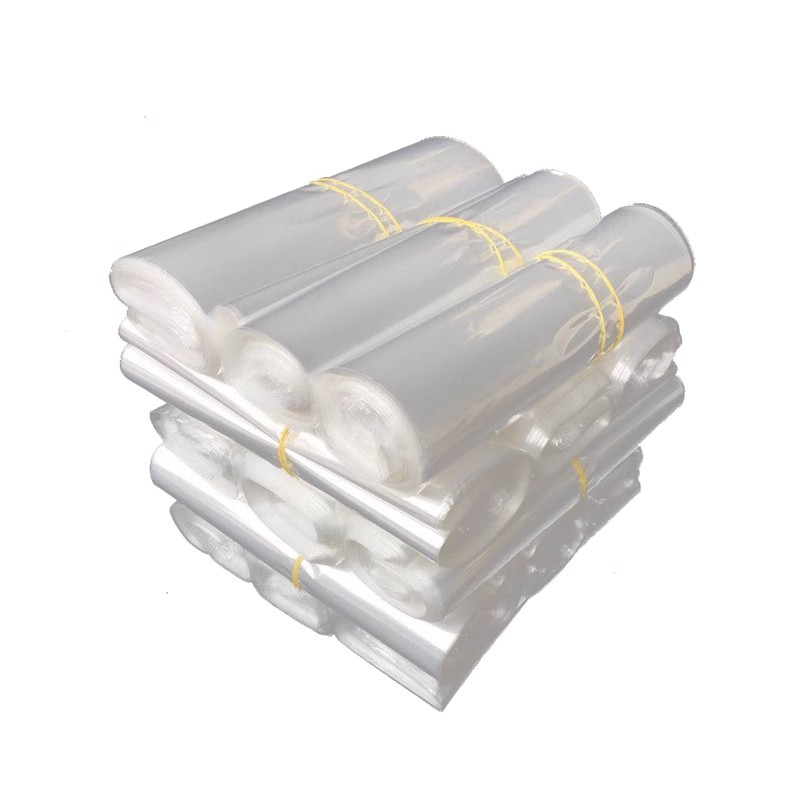

Xiamen Guanhua Heat Shrink Wrap Packaging is perfect for various applications, from winterizing boats and massive structures to packaging small retail products. It is available in rolls, bags, and tubing. Understanding basic info about shrink wrap will ensure you purchase the right product.

Often confused with stretch film, Heat Shrink Wrap Packaging comprises a wide variety of plastic materials designed to shrink after heat is applied. Conventional plastics used are polyolefin, PVC, polyethylene, and polypropylene.

Heat Shrink Wrap Packaging is a solution worldwide—everything from wrapping frozen pizzas to bundling hardware. The excellent film, material thicknesses, and machines can help make production more efficient and streamlined.

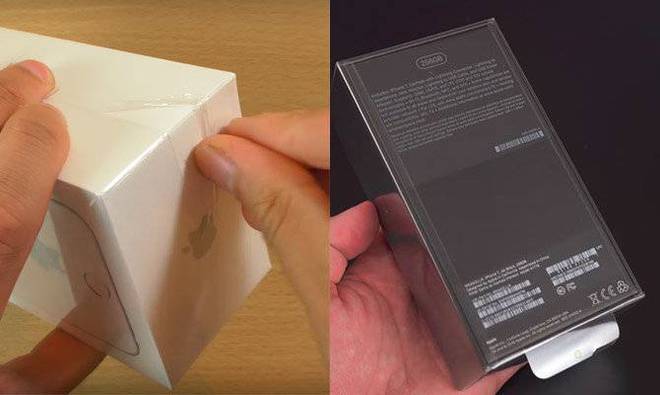

Heat Shrink Wrap Packaging use and application of shrink wrap film can vary depending on the material used. Although different materials can require various forms of application, the basic requirements remain the same. The wrapped product needs to be inserted into the shrink film, open ends to be sealed, and heat is applied to the film. In some instances, open ends do not require a seal.

Machine Equipment Advantages:

1. Adopt new technology design, human-machine interface, simple and clear, humanized operation mode.

2. Classic shape, beautiful, novel structure, unique, easy operation and maintenance. Electronic sensing PE film delivery, sending film stable, fast and convenient for membrane.

3. The third generation SHF thermostatic seal cutter, Edge firmly, cut off quickly. Sealing strength of cold cut hot knife more than 3 times, uniform sealing formation, the service life is 80 times the hot sealing knife.

4. Shrinkage chamber using circulating air supply technology, reasonable structure, thermal insulation, high temperature precision, shrink packaging effect is better.

5. Supporting Germany's Siemens, Japan's OMRON, UNIQUC and other advanced control components, well-equipped.

6. The gap between the cooling channel and the contraction channel is greater than 500mm, so that the cold wind can be avoided and the heat loss will be reduced.

7. Film-sending motor, new circulation wind motor with overload protection device; add OMRON intermediate relay, to protect the circuit security.

8. This model is exclusive YCTD Innovative products to fill the China gap, the national patent technology.

We offer customization services, including custom colors, sizes, shapes and more!

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी