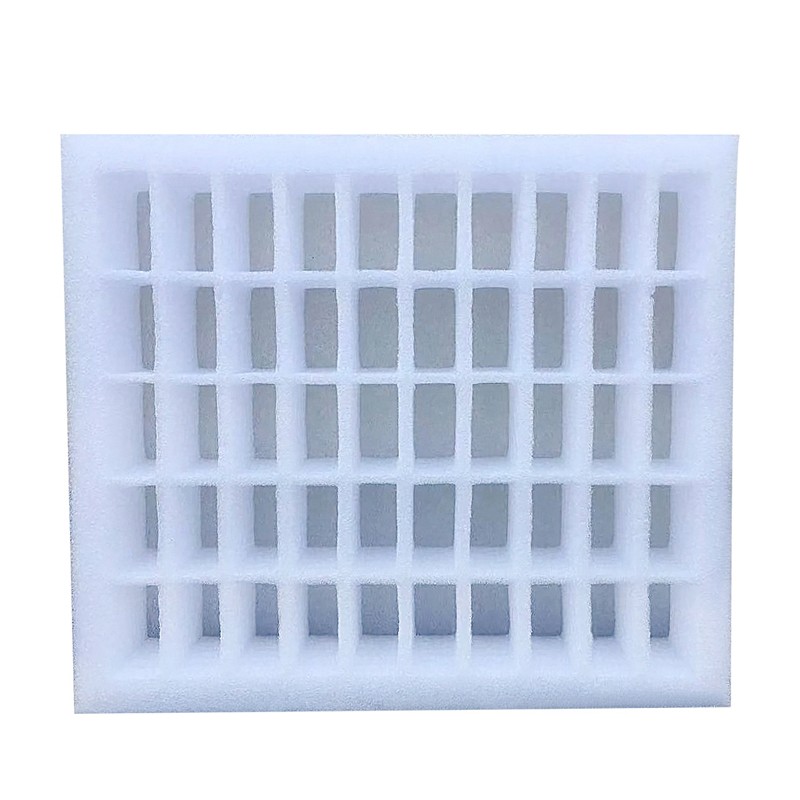

EPE Molded Foam Inserts

Send Inquiry

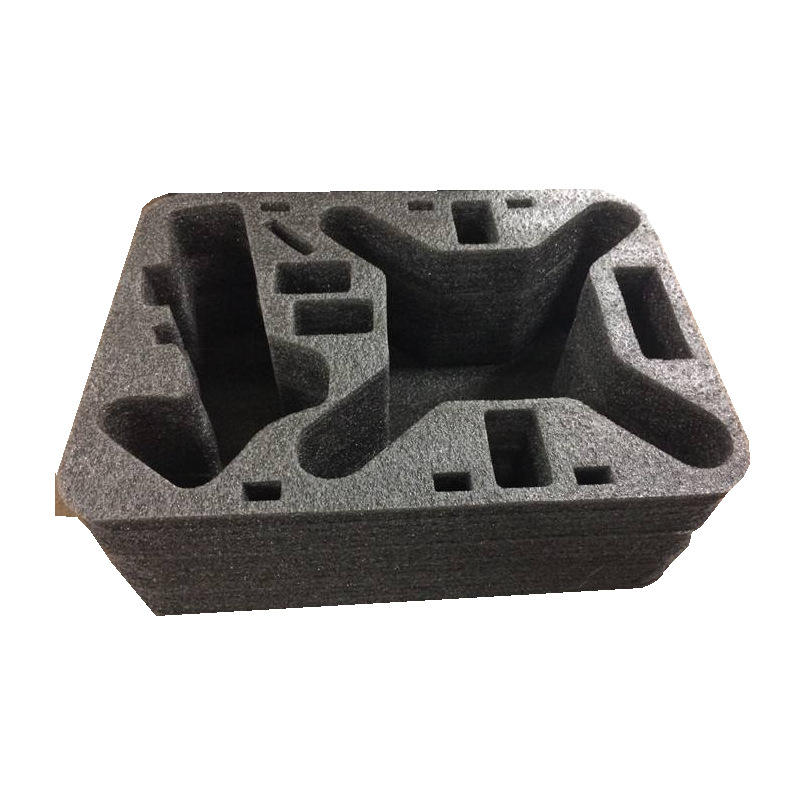

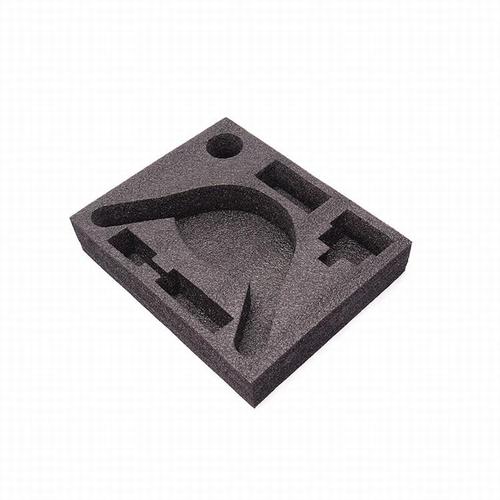

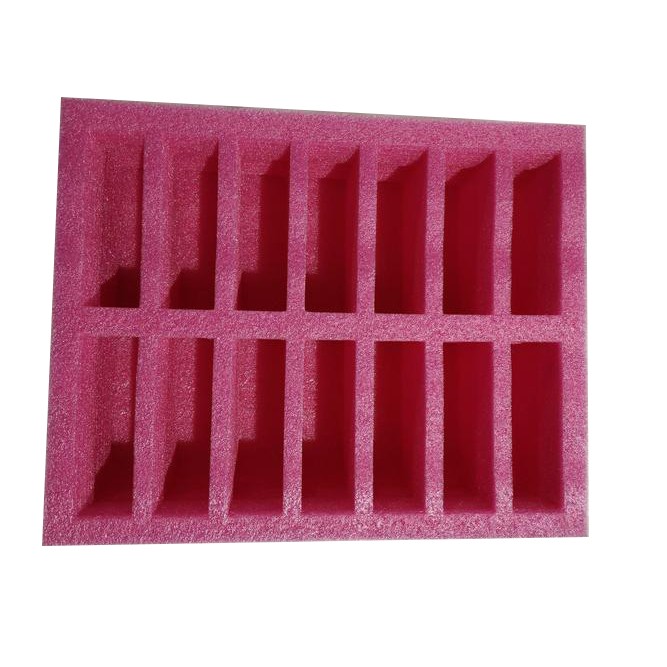

One of the primary advantages of EPE molded foam inserts is their ability to conform to the shape of the product they are protecting. This custom fit ensures that the item is securely held in place, reducing the risk of damage caused by shifting or impact. Additionally, EPE foam is lightweight, which helps to minimize shipping costs and make handling easier for workers. This makes it an ideal choice for companies looking to reduce their carbon footprint and improve their sustainability efforts.

Furthermore, EPE molded foam inserts offer excellent cushioning properties, absorbing shock and vibration to prevent breakage or scratches on delicate items. This is particularly important for products that are sensitive to impact, such as electronics, glassware, and medical devices. By using EPE foam inserts, manufacturers can ensure that their products arrive at their destination in pristine condition, improving customer satisfaction and reducing returns.

In addition to their protective qualities, EPE molded foam inserts are also highly versatile. They can be easily customized to fit a wide range of products, from small electronic components to large industrial machinery. This flexibility makes them a popular choice for companies in various industries, including electronics, automotive, and healthcare. Whether you need to protect a single item or create a multi-layered packaging solution, EPE foam inserts can be tailored to meet your specific requirements.

The use of EPE molded foam inserts has had a significant impact on the packaging industry, revolutionizing the way products are protected and shipped. By providing a reliable and cost-effective solution for packaging fragile items, EPE foam has helped companies streamline their operations and improve their bottom line. In addition, the lightweight and recyclable nature of EPE foam aligns with the growing demand for sustainable packaging solutions, making it an attractive option for environmentally conscious businesses.

In conclusion, EPE molded foam inserts offer numerous benefits for companies looking to enhance the protection of their products during transportation and storage. With their custom fit, cushioning properties, and versatility, EPE foam inserts have become a staple in the packaging industry, providing a reliable and cost-effective solution for companies of all sizes. As the demand for sustainable packaging solutions continues to grow, EPE foam inserts are poised to play a key role in helping businesses meet their environmental goals while ensuring the safe delivery of their products.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी