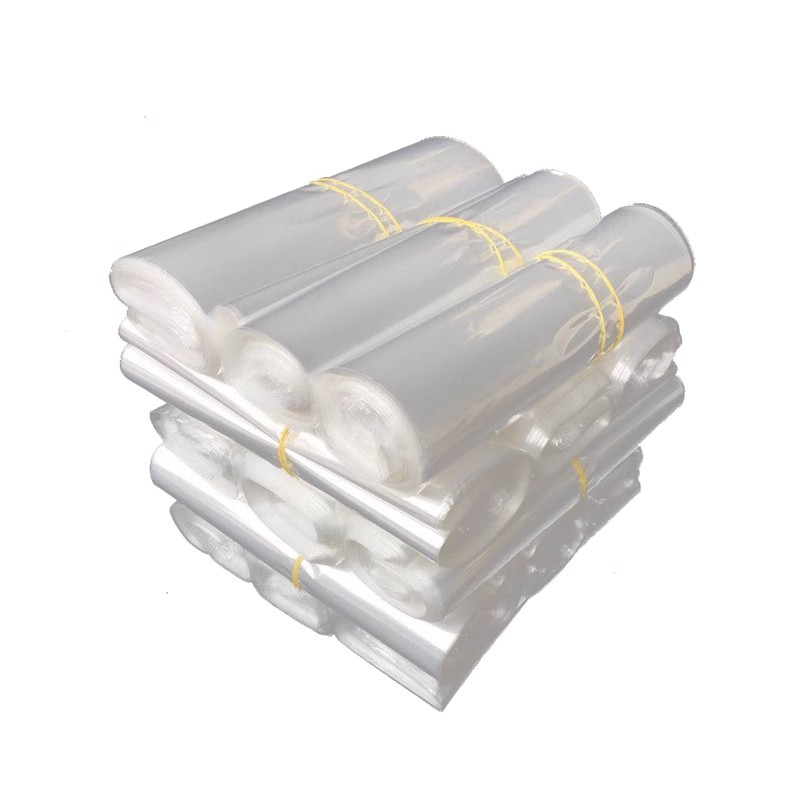

Thermo Shrink Bags

Send Inquiry

Thermo shrink bags are typically composed of polyolefin, polyethylene, or PVC films. These materials are engineered to undergo shrinkage when subjected to elevated temperatures, a process achieved through the use of heat guns or ovens. When heated, the bags conform tightly around the contours of the products they encase, providing a secure and protective wrap that enhances both aesthetic appeal and functionality. This snug fit not only showcases the packaging contents effectively but also protects items from dust, moisture, and contamination, thereby prolonging product shelf life.

One of the most notable applications of thermo shrink bags is in the food industry. The ability to extend the freshness of perishable goods is paramount, and thermo shrink bags facilitate this by creating a seal that prevents the entry of oxygen—one of the principal causes of food spoilage. Moreover, such bags can be used for vacuum sealing, which further enhances their preservative properties by reducing the need for preservatives and additives. This environmentally friendly aspect appeals to consumers who are increasingly conscious of sustainability in their purchasing decisions.

Beyond food packaging, thermo shrink bags are widely utilized in the retail and manufacturing sectors. They are particularly effective for bundling multiple products together, offering convenience for both the retailer and the consumer. For instance, items such as books, stationery, and electronic components can be packaged in shrink bags for easier handling and transportation. Additionally, the transparency of the material allows for visibility of the product, enhancing consumer engagement at the point of sale. In the decorative sector, custom-printed thermo shrink bags enable businesses to reinforce branding and marketing strategies effectively.

The advantages of thermo shrink bags extend beyond their protective qualities and aesthetic appeal. Their lightweight nature contributes to reduced shipping costs, making them an economically viable option for businesses seeking to optimize logistics. Moreover, the compatibility of thermo shrink bags with automated packaging equipment promotes efficiency in production lines, enabling faster turnaround times without sacrificing quality. As a result, companies can meet consumer demands by providing timely delivery of products while maintaining a high standard of packaging integrity.

In conclusion, thermo shrink bags represent a significant advancement in packaging technology, combining functionality, versatility, and aesthetic appeal. Their widespread application across various sectors, particularly in food preservation and product bundling, underscores their importance in modern business practices. While environmental considerations remain a pertinent issue, ongoing developments in sustainable materials offer hope for more eco-friendly options in the future. Ultimately, thermo shrink bags are not just a packaging solution; they are a testament to the ongoing evolution of the packaging industry in response to consumer needs and environmental responsibilities.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी