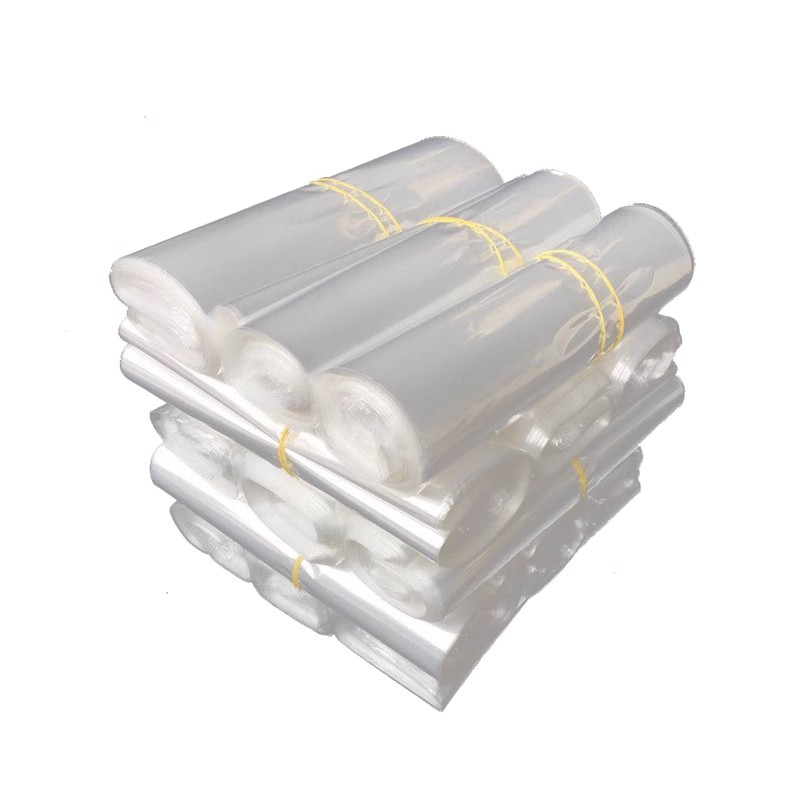

Shrink Plastic Film

Shrink plastic film is a versatile polymer material that has garnered widespread acclaim across various industries primarily due to its unique properties and applications. It is manufactured from materials such as polyethylene, polyvinyl chloride (PVC), or polyolefin, which, when subjected to heat, contract tightly around an object. This essay explores the characteristics of shrink plastic film, its extensive applications, and the environmental considerations that accompany its use.

Send Inquiry

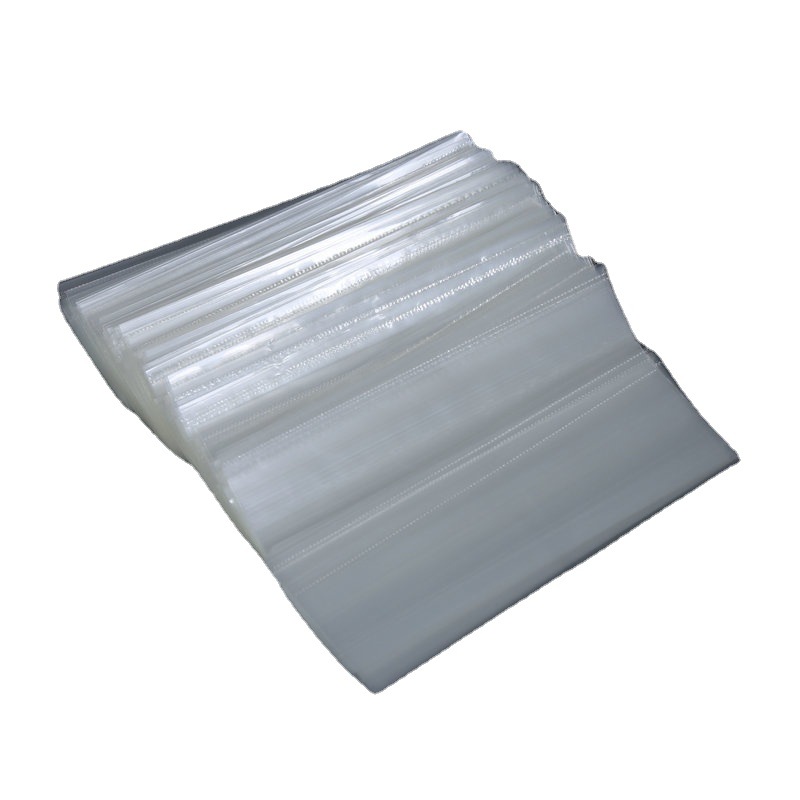

At the heart of shrink plastic film's functionality lies its thermoplastic properties. When exposed to heat, the film undergoes a significant reduction in size, adhering closely to the contours of the items it encases. This quality not only enhances the aesthetic appeal of products through a smooth and tightly wrapped exterior but also serves as a protective barrier, safeguarding contents from dust, moisture, and other environmental factors. Moreover, shrink film is lightweight, which contributes to reduced shipping costs and energy consumption, making it an economically advantageous choice for manufacturers and retailers alike.

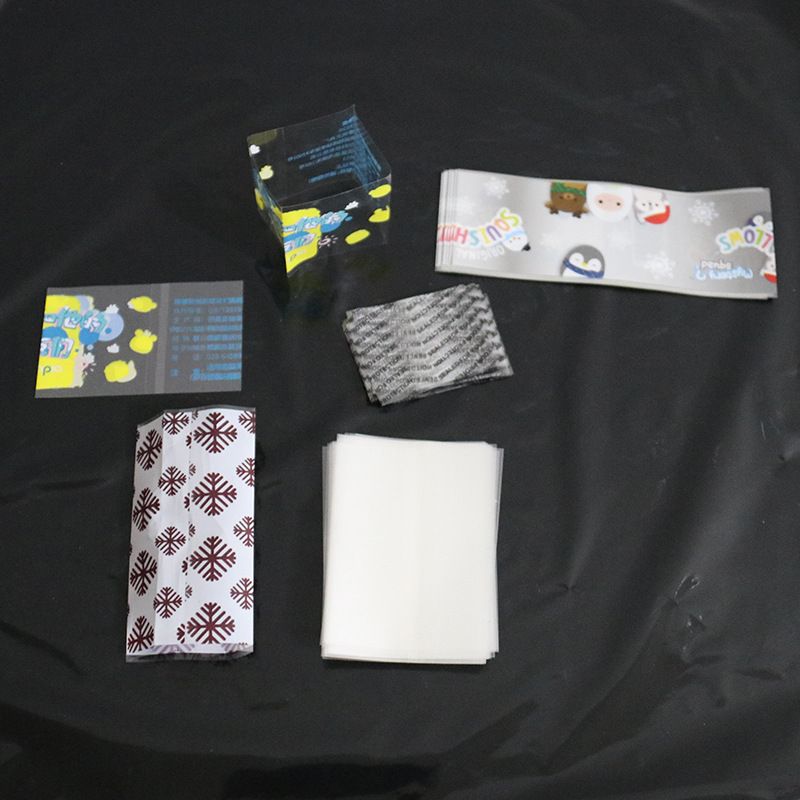

The applications of shrink plastic film are both diverse and impactful. In the packaging industry, the film is predominantly utilized for bundling products, creating tamper-proof seals, and ensuring the stability of merchandise during transit. Additionally, shrink film plays a critical role in the food sector, where it preserves freshness and extends shelf life by providing an airtight seal that inhibits the growth of bacteria and mold. Beyond packaging, shrink plastic film is also employed in the manufacturing of promotional materials, including shrink sleeves and labels that enhance brand visibility. The film's ability to conform to different shapes and sizes has enabled creative packaging solutions that captivate consumer attention and foster brand recognition.

In conclusion, shrink plastic film represents a significant innovation in the realms of packaging and product protection, boasting a myriad of applications across various industries. Despite its advantages, the environmental implications surrounding its use necessitate a critical examination of alternatives and sustainable practices. As industries continue to evolve, the challenge remains to balance functionality with environmental responsibility, ensuring that the benefits of shrink plastic film can be enjoyed without compromising the health of our planet.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी