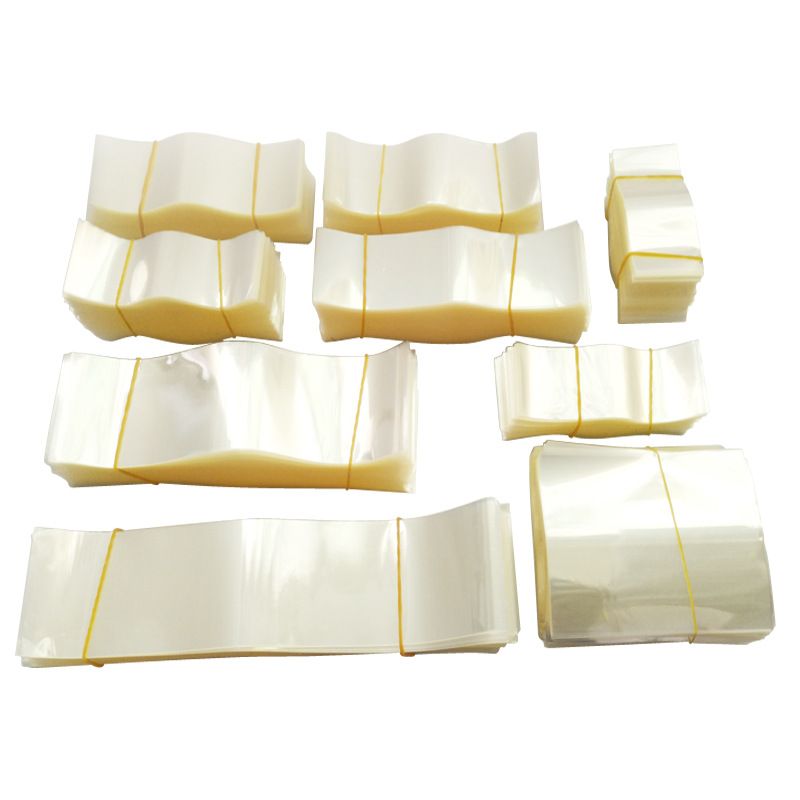

PVC Shrink Bands

Send Inquiry

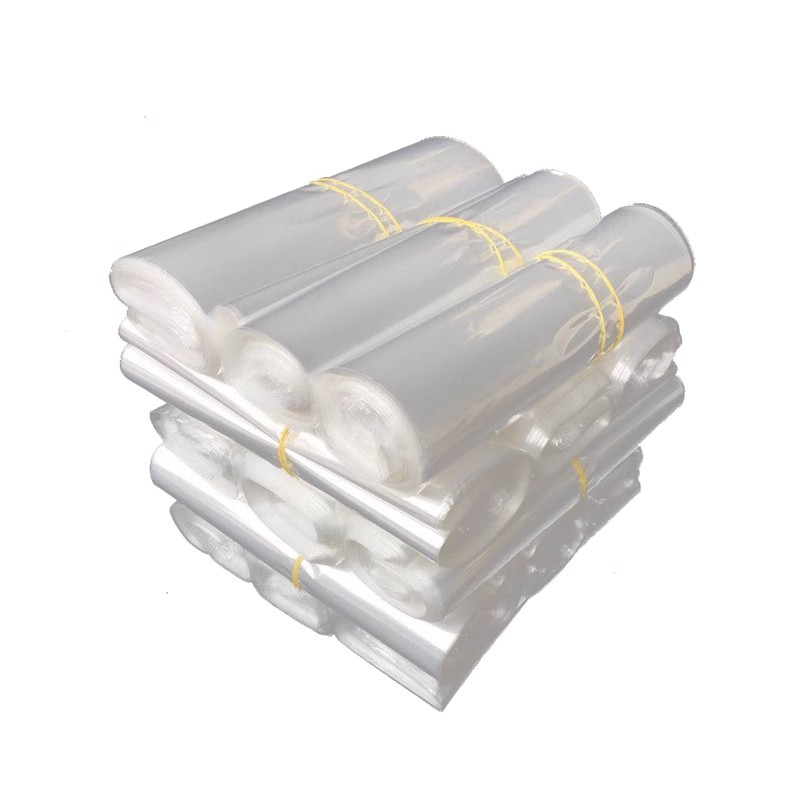

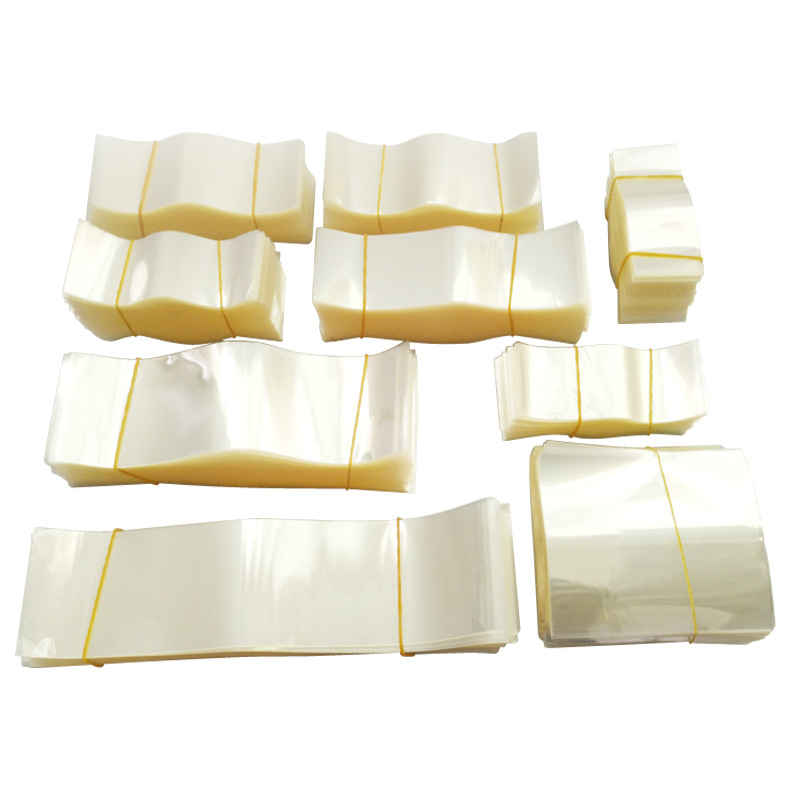

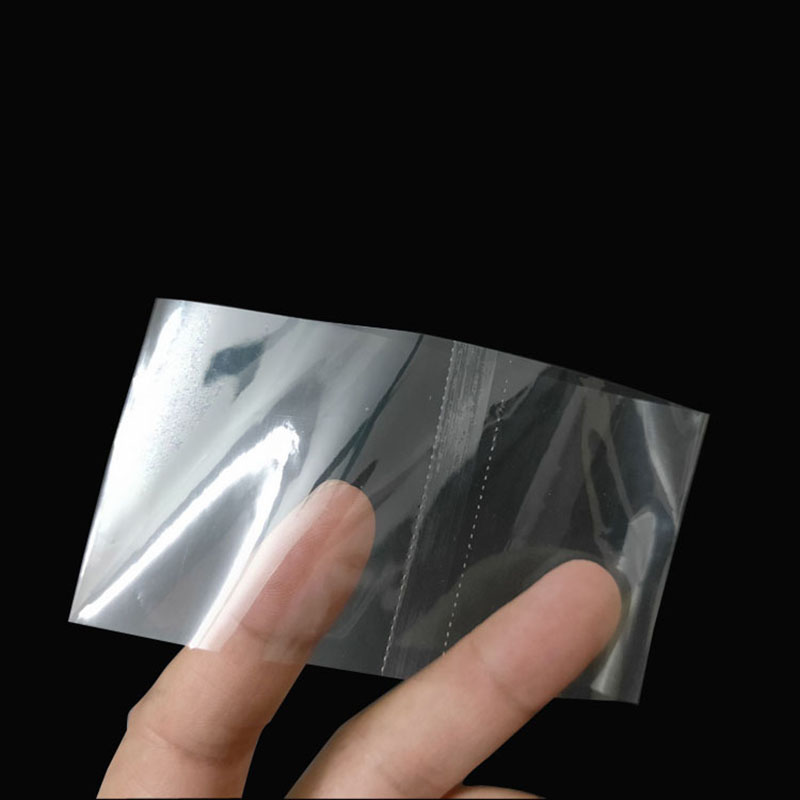

PVC shrink bands are tubular films manufactured from polyvinyl chloride that undergo a process of heating to create a secure fit around a product. These bands start as flat sheets or rolls and are then cut, shaped, and applied to products before being subjected to heat. Upon heating, the PVC film shrinks tightly around the item, creating a tamper-evident seal that securely adheres to the contours of the container.

1. Durability: PVC is known for its strength and resilience. Shrink bands made from this material provide significant protection against damage during transport and handling.

2. Clarity: The optical clarity of PVC allows for excellent visibility of the product within the packaging. This feature is particularly advantageous for retailers looking to showcase their products appealingly.

3. Variety of Sizes and Thicknesses: PVC shrink bands are available in various sizes, thicknesses, and colors, making them suitable for a wide range of products—from food and beverages to cosmetics and electronics.

1. Product Protection

PVC shrink bands provide a protective layer that prevents contaminants, moisture, and dirt from coming into contact with the product. This safeguard is particularly crucial in food packaging, where hygiene is paramount.

2. Cost-Effectiveness

Compared to other forms of packaging, PVC shrink bands are often more economical. Their lightweight nature reduces shipping costs, while their ability to fit various products reduces the need for multiple types of packaging solutions.

3. Flexibility and Customization

The capability to customize PVC shrink bands with print and graphics adds value to branding efforts. Companies can use these bands to convey important information, promote brand identity, and enhance shelf appeal through vibrant designs and colors.

4. Ease of Use

Application of PVC shrink bands is straightforward, making them ideal for both manual and automated packaging processes. Once the bands are applied, the heat shrink process is quick and efficient, resulting in a secure and polished final presentation.

PVC shrink bands are widely utilized across various industries, including:

Food and Beverage: Providing a seal for jars, bottles, and containers while ensuring freshness and hygiene.

Cosmetics and Personal Care: Enhancing the presentation of lotions, perfumes, and other beauty products, while preventing tampering.

Pharmaceuticals: Offering assurance of product integrity and safety for medications and health supplements.

Consumer Electronics: Protecting packages against damage and tampering while showcasing product features.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी