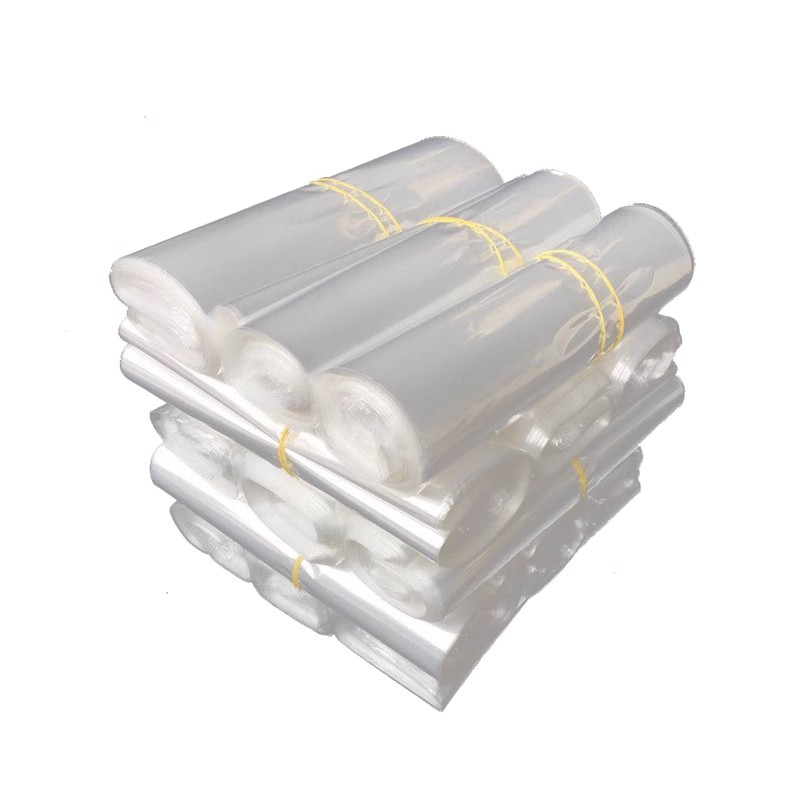

PVC Heat Shrink Film

Send Inquiry

One of the most notable characteristics of PVC heat shrink film is its excellent shrinkage capability. When subjected to elevated temperatures, typically ranging from 70°C to 120°C, the film contracts tightly around the object it wraps, ensuring a secure fit. This property is primarily due to the molecular structure of PVC, which allows for significant alteration in dimensions upon heating. The resultant tightness not only provides an aesthetically pleasing appearance but also enhances product protection against environmental factors such as moisture, dust, and physical damage. This makes PVC heat shrink film an ideal choice for packaging perishable food items, electronics, and various retail products, contributing to the extension of shelf life and preservation of quality.

Another pivotal advantage of PVC heat shrink film is its durability. This material exhibits remarkable resistance to punctures, tears, and abrasions, ensuring that the contents remain safeguarded during transit and handling. Additionally, it possesses inherent properties that protect against UV radiation and chemical exposure, offering a fortified barrier for products that may otherwise degrade under harsh conditions. This resilience is crucial not only for manufacturers seeking to maintain product integrity but also for consumers who value reliability and quality in packaging.

Furthermore, the versatility of PVC heat shrink film extends into the realm of customization. The film can be produced in a variety of gauges and can be printed with branding or product information, enhancing marketing appeal. The ability to tailor the film to specific products or consumer preferences has made it a popular choice in retail environments where visual presentation and brand identity are paramount. This customization capability, combined with its protective features, positions PVC heat shrink film as a critical tool for businesses aiming to differentiate themselves in a competitive market.

In conclusion, PVC heat shrink film stands as a quintessential example of modern material science, offering exceptional shrinkage properties, durability, and customization options that cater to diverse industrial needs. Its role in enhancing product protection and appearance cannot be understated. However, as industry standards evolve alongside growing environmental consciousness, it is imperative that stakeholders in the production and usage of PVC heat shrink film consider sustainable practices that align with global efforts to reduce plastic waste. By balancing functionality with responsibility, the industry can continue to harness the benefits of PVC heat shrink film while contributing to a healthier planet.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी