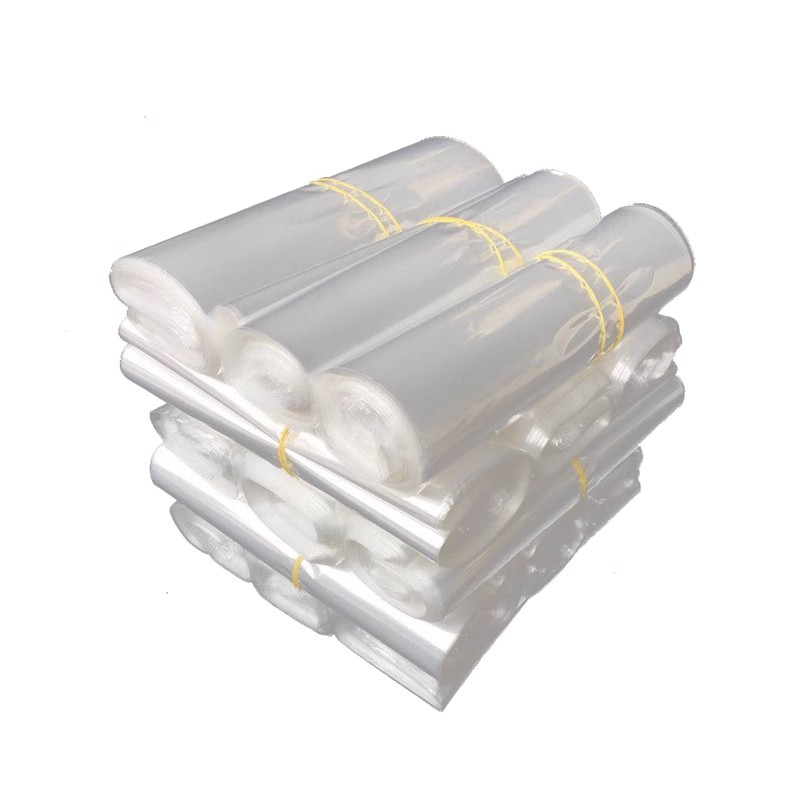

PET Heat Shrink Sealing Film

Send Inquiry

PET heat shrink sealing films are characterized by their exceptional tensile strength and impressive barrier properties, making them ideal for preserving the integrity of various products. The material displays excellent resistance to moisture, oxygen, and UV radiation, which is paramount in prolonging shelf life and maintaining product freshness. The films are produced in varying thicknesses and can be engineered to shrink uniformly when subjected to heat, conforming snugly around the contours of products. This feature not only enhances the visual appeal of packaged goods but also provides a protective layer against physical damage and contamination.

Moreover, PET films are known for their low shrink temperatures and high clarity, allowing consumers to view the product without the need for unwrapping. This transparency can significantly influence purchasing decisions, as customers often prefer products that are visually accessible. The combination of durability and aesthetic attributes positions PET heat shrink sealing films as a leading choice for both manufacturers and retailers.

The versatility of PET heat shrink sealing films lends itself to a myriad of applications across various sectors. In the food and beverage industry, the films are extensively used for packaging items such as bottled drinks, snack foods, and even perishables. Their superior sealing properties ensure that products remain fresh while reducing spoilage rates. Additionally, PET films are employed in the pharmaceutical and cosmetic industries, where they act as a barrier against contaminants, thus ensuring that products retain their intended efficacy.

Beyond traditional packaging, PET heat shrink films are also utilized in bundling and grouping products. The films can secure multiple items together, providing a cohesive presentation while facilitating ease of transport. This application is particularly beneficial in retail settings, where promotional products or gift sets are packaged together, enhancing their marketability.

The adoption of PET heat shrink sealing films brings forth numerous advantages that contribute to the overall efficiency and sustainability of packaging processes. To begin with, their ability to provide a secure seal not only protects products but also reduces the likelihood of tampering, a pivotal concern for both consumers and manufacturers. This security can bolster consumer confidence in product safety, ultimately enhancing brand loyalty.

Furthermore, PET is a recyclable material, which aligns with the growing demand for sustainable packaging solutions. The recycling process for PET is well-established, facilitating a circular economy where materials can be repurposed, thereby mitigating environmental impact. As global awareness of environmental issues increases, the use of recyclable materials like PET in packaging becomes not just a regulatory requirement but also a competitive advantage.

Finally, PET heat shrink films can contribute to cost savings in manufacturing and logistics. Their lightweight nature reduces shipping costs, while their durability minimizes the likelihood of product damage during transit, translating to fewer losses and increased profitability for businesses.

In summary, PET heat shrink sealing film stands as a compelling solution in the packaging industry, characterized by its remarkable durability, aesthetic transparency, and application versatility. Its benefits, ranging from enhanced product protection to environmental sustainability, position it as an integral component in modern packaging strategies. As businesses continue to prioritize consumer safety and environmental responsibility, the role of PET heat shrink sealing films is poised to grow, reinforcing their place as a vital innovation in packaging technology.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी