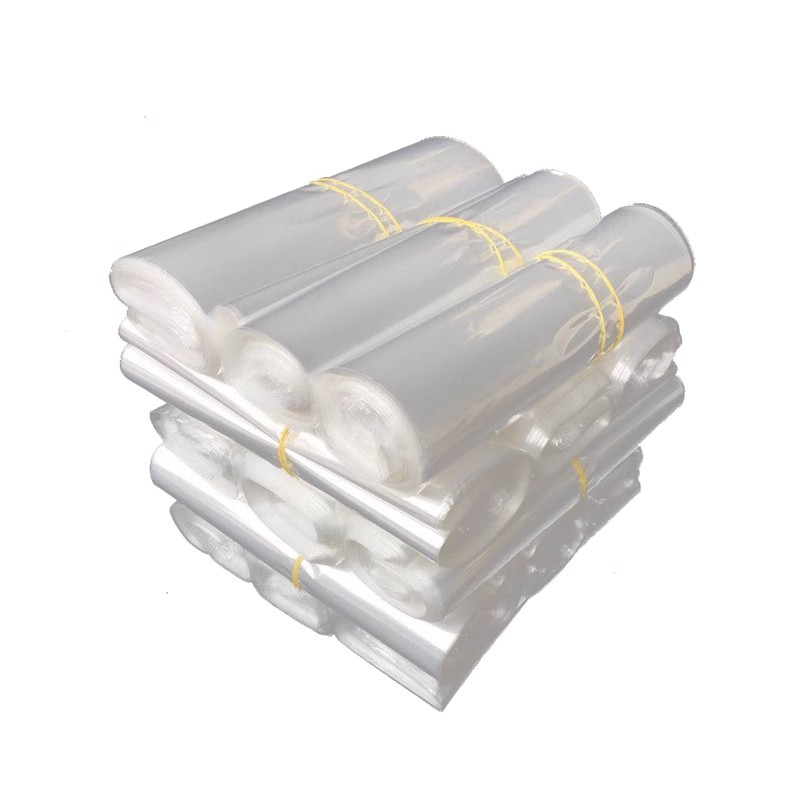

Heat Shrinkable for Bottles

In the contemporary realm of packaging, the choice of materials and methodologies plays a pivotal role in ensuring product integrity, aesthetic appeal, and brand recognition. Among the myriad of packaging solutions available, Heat Shrinkable for Bottles have emerged as a prominent choice, This innovative packaging technique not only enhances the protection of bottled products but also offers several advantages that contribute to the overall efficiency of the packaging process.

Send Inquiry

Heat Shrinkable for Bottles are made from polymer plastics, such as polyolefin or PVC, which exhibit the unique property of shrinking when exposed to heat. This characteristic is harnessed in the bottling industry, where sleeves are applied to bottles during the packaging process. Initially, the sleeves are placed loosely around the bottles, and upon heating, they conform tightly to the contours of the bottle, creating a tight and secure fit. This shrink-to-fit technology not only provides an appealing visual uniformity but also ensures that the label or design remains intact, thereby enhancing brand visibility.

One of the primary advantages of using heat shrinkable sleeves in bottling is their ability to protect products from various external factors. The sleeves act as a barrier against moisture, dust, and contaminants, which can compromise the integrity of the product, particularly in the case of beverages and other liquid products. Furthermore, these sleeves can provide additional security features, such as tamper-evident seals, which can deter unauthorized access and assure consumers of the product’s safety.

Additionally, heat shrinkable sleeves present a significant advantage in terms of versatility. They can be utilized for a wide range of bottle shapes and sizes, making them a flexible option for manufacturers. Whether for cylindrical, square, or uniquely shaped containers, heat shrinkable sleeves can be custom-designed to fit. This adaptability is crucial in a rapidly changing market, where consumer preferences and product designs may shift frequently.

Moreover, the implementation of heat shrink technology can contribute to sustainability efforts within the packaging industry. As businesses increasingly seek to reduce their environmental impact, heat shrinkable sleeves can be produced using recyclable materials. Advanced manufacturing processes also ensure efficient use of materials, minimizing waste and endorsing the principles of circular economy. Consequently, companies that prioritize sustainable practices can leverage heat shrinkable sleeves to align with consumer values while maintaining the integrity of their products.

In conclusion, heat shrinkable sleeves represent a dynamic and effective packaging solution for the bottling industry. Their ability to enhance product protection, provide aesthetic appeal, and adapt to various shapes and sizes makes them an invaluable asset for manufacturers. Additionally, the potential for sustainable practices associated with the use of these materials positions them favorably in an increasingly eco-conscious market. As packaging technology continues to evolve, heat shrinkable sleeves will undoubtedly remain a significant trend in ensuring that bottled products meet both consumer expectations and operational efficiencies.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी