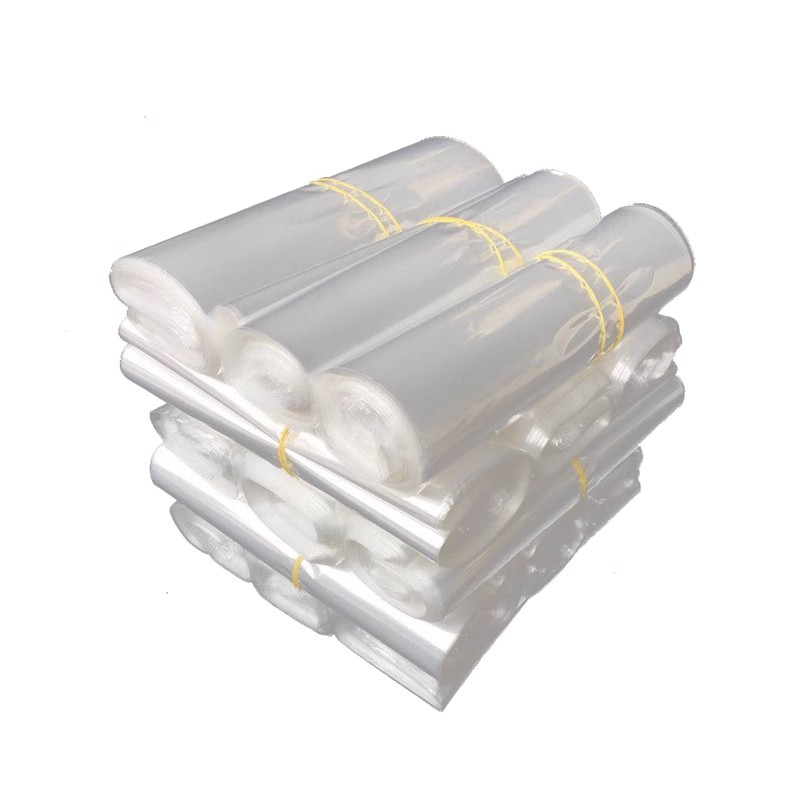

Heat Shrink Seal for Bottle

In contemporary packaging technology, the heat shrink seal for bottle has emerged as a pivotal component in ensuring the integrity and safety products. This innovative sealing method is not merely a cosmetic accessory but serves several critical functions essential to the beverage and consumer goods industries. The adoption of heat shrink seals offers enhanced protection against tampering, contamination, and product degradation, thereby establishing a robust framework for both product integrity and consumer trust.

Send Inquiry

Heat shrink seal for bottle are produced from thermoplastic materials that, when heated, contract to fit snugly around the closure of a bottle. This unique property is harnessed in various applications, particularly in the food and beverage sector, where maintaining the quality of the product is paramount. The process typically involves the application of a sleeve of heat-sensitive plastic over the bottle’s cap or neck. Upon heating, the material shrinks tightly around the bottle, forming a secure barrier that is difficult to remove without visible damage.

One of the most significant advantages of heat shrink seals is their ability to deter tampering. In an era marked by increasing consumer vigilance regarding product safety, an effective seal can serve as a psychological deterrent against potential adulteration. The presence of a heat shrink seal not only reassures consumers of the product's safety but also protects the manufacturer by reinforcing brand integrity. A broken seal is often perceived as a signal that a product may have been compromised, which can lead to a loss of consumer confidence and, ultimately, a decline in sales.

Moreover, heat shrink seals play a critical role in extending the shelf life of bottled products. By providing a tight seal, they minimize the ingress of moisture and contaminants, which can lead to spoilage or degradation of perishable goods. This property is particularly advantageous for beverages prone to oxidation or contamination by external elements. Consequently, manufacturers utilizing heat shrink technology can enhance their product’s longevity and maintain its quality over time, thereby reducing waste and improving economic returns.

Further emphasizing their versatility, heat shrink seals can be customized to offer branding opportunities. Through the use of various colors, prints, and finishes, manufacturers can leverage these seals not just as functional safety features but also as marketing tools. Vibrant, elaborately designed seals can attract consumers’ attention and enhance brand visibility on crowded retail shelves. This dual benefit of functionality and aesthetics is appealing to businesses seeking to differentiate their products in a competitive marketplace.

In conclusion, heat shrink seals represent a significant advancement in bottle packaging, offering unparalleled benefits in terms of tamper resistance, shelf life extension, and branding. As industries continue to evolve and consumer demands become more sophisticated, the reliance on such innovative technologies is likely to expand. While challenges remain, the integration of sustainable practices in the production and use of heat shrink seals can help reconcile environmental concerns with the essential functions they provide. Thus, as both a protective measure and marketing tool, heat shrink seals stand as a testament to the dynamic interplay between functionality and consumer engagement in modern packaging solutions.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी