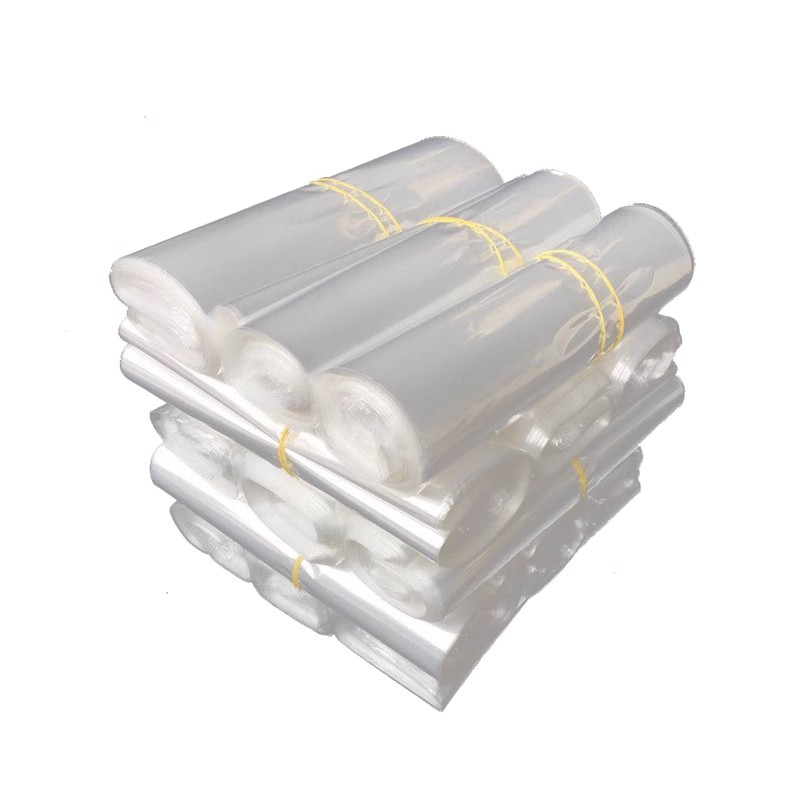

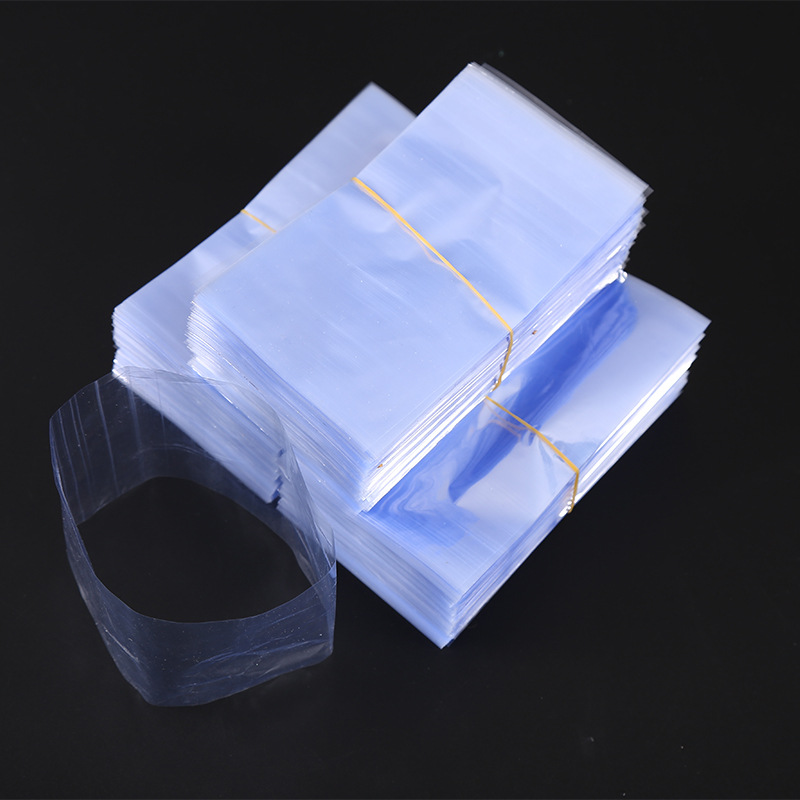

Heat Shrink Plastic Film

In an era marked by innovation and efficiency, heat shrink plastic film has emerged as an indispensable material across a multitude of industries. This specialized film, composed primarily of polyolefin, polyvinyl chloride (PVC), or polyethylene, exhibits a remarkable ability to shrink and conform to the shape of an object when subjected to heat. Its unique properties render it a vital component in packaging, insulation, and protective applications, thereby revolutionizing various operational practices.

Send Inquiry

At the core of heat shrink plastic film’s appeal is its exceptional versatility. In the packaging industry, it serves a dual purpose: it not only secures products but also enhances their visual presentation. When applied to consumer goods, heat shrink film provides a tamper-evident seal that assures consumers of product integrity. Moreover, this type of film can be printed with company branding and design elements, adding marketing value while maintaining the product's visibility. In sectors ranging from food and beverage to electronics and pharmaceuticals, the application of heat shrink plastic film has become a standard practice, streamlining operations and improving overall product aesthetics.

Another significant advantage of heat shrink plastic film lies in its role in insulation and protective materials. The film's thermal properties contribute to its use as an insulating layer for wires and cables, safeguarding them against environmental factors such as moisture, dust, and abrasion. This characteristic is particularly important within the electrical and automotive industries, where the reliability of components is paramount. The ability of heat shrink film to provide a snug fit ensures durability and longevity, ultimately reducing maintenance costs and enhancing safety.

Furthermore, the environmental implications of heat shrink plastic film warrant consideration. While plastic materials have garnered criticism for their ecological impact, advancements in production technologies have led to the development of recyclable and biodegradable options within the realm of heat shrink film. Manufacturers are increasingly adopting sustainable practices to lessen their environmental footprint, thereby aligning with global efforts towards sustainability. The utilization of such materials signals a positive shift in the industry, promoting responsible consumption while maintaining the benefits associated with heat shrink packaging.

In conclusion, heat shrink plastic film represents a confluence of functionality, versatility, and sustainability in modern applications. Its widespread use in packaging, insulation, and protection underscores its significance in various sectors. As industries continue to evolve, the adaptation of heat shrink film that aligns with ecologically responsible practices will be crucial. Embracing this technology not only improves operational efficiency but also promotes a more sustainable future, making heat shrink plastic film a critical component of contemporary manufacturing and packaging solutions.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी