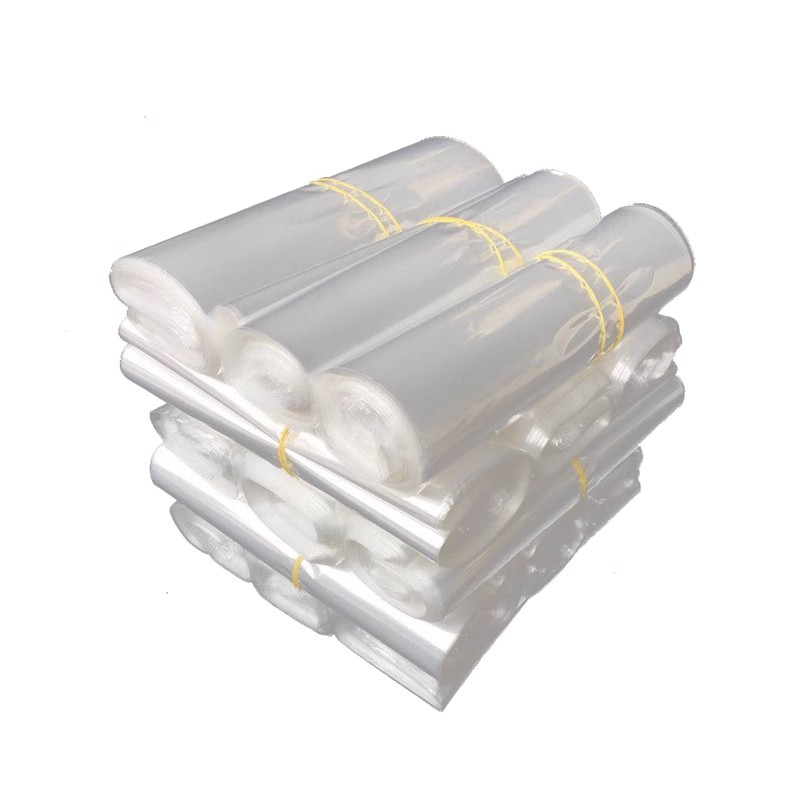

Heat Shrink Film

Send Inquiry

At the core of its functionality, heat shrink film exhibits a remarkable ability to conform tightly around the object it encases when subjected to heat. This characteristic is attributable to its molecular structure, which is altered during the manufacturing process. Initially produced as a flat sheet, the film is heated, causing it to shrink to fit the contours of the product it wraps. This feature not only enhances the aesthetic appeal of the packaging but also provides an effective barrier against dirt, moisture, and contaminants, thereby preserving the integrity of the product within.

One of the most significant applications of heat shrink film is in the packaging of consumer goods. From food products to electronics, the film serves as a protective layer, ensuring that items remain unscathed during transportation and storage. In the food industry, for instance, heat shrink wrapping extends the shelf life of perishables by creating a vacuum-like seal that inhibits exposure to air and pathogens. Additionally, branded products benefit from the visual appeal and tamper-proof nature of heat shrink film, which aids in marketing efforts while maintaining consumer trust.

Moreover, heat shrink film is integral to the construction and automotive industries. It is often utilized to bundle and protect materials like insulation, electrical wiring, and pipes, safeguarding them against environmental factors that could compromise their efficacy. In the automotive sector, heat shrink tubing is frequently employed to insulate and protect electrical connections. This application is crucial in preventing short circuits and ensuring the longevity of vehicle components.

The advantages of heat shrink film extend beyond its protective qualities. It is lightweight and cost-effective, providing a practical solution for manufacturers seeking to reduce shipping costs without compromising product safety. The film can also be printed upon, enabling companies to convey branding and product information effectively, thus merging functionality with marketing strategy. Furthermore, heat shrink film is available in various thicknesses and shrink ratios, allowing for customization to meet diverse packaging requirements.

In conclusion, heat shrink film stands out as a pivotal innovation in the packaging domain, offering an array of benefits that cater to numerous industries. Its protective qualities, versatility in application, and cost-effectiveness make it an indispensable tool for safeguarding products and enhancing consumer appeal. As businesses continue to seek sustainable and efficient packaging solutions, the role of heat shrink film is poised to expand further, solidifying its position as a critical component in modern manufacturing and distribution practices.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी