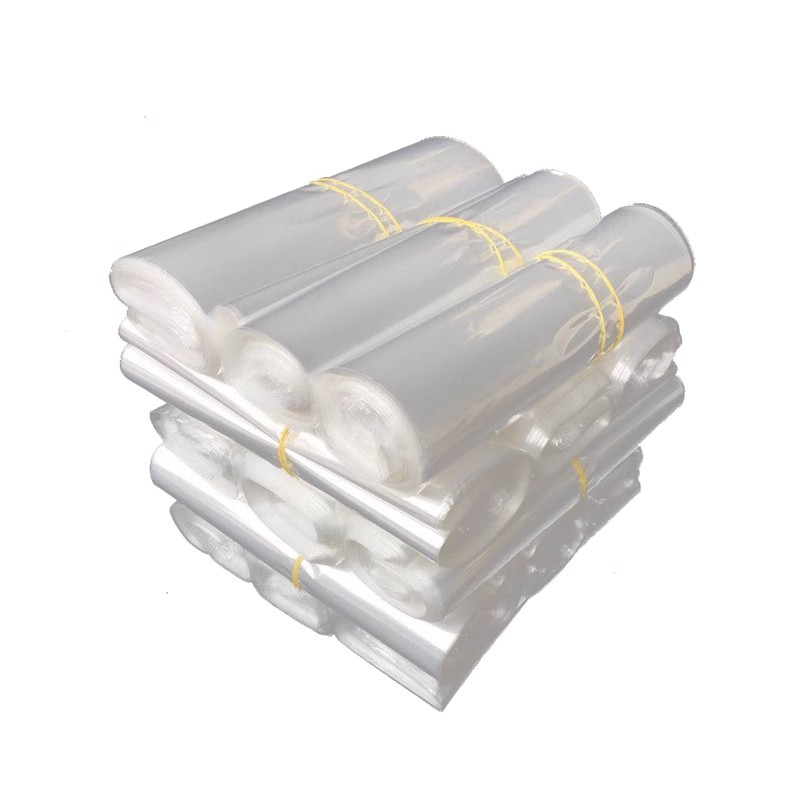

Heat Shrink Bags

In the realm of packaging technologies, heat shrink bags have garnered significant attention for their unique properties and versatility. These specialized plastic films, made typically from polyolefin or PVC, have become indispensable across various industries, ranging from food packaging to product bundling and even industrial applications. This essay explores the characteristics, applications, advantages, and environmental considerations associated with heat shrink bags.

Send Inquiry

Heat shrink bags are designed to conform tightly to the contours of the products they encase. This adaptability is achieved through a two-step process involving heat application. Initially, the bags are manufactured in a flat form or as tubing. When exposed to heat—commonly via a heat gun or shrink tunnel—the material shrinks to fit snugly around the item, creating a vacuum-like seal. This not only enhances the aesthetic appeal of packaged goods but also provides protection against dust, moisture, and contamination.

One of the primary applications of heat shrink bags is in the food industry. They are widely utilized for packaging meats, cheeses, and other perishables. The tight seal formed by shrink wrapping extends the shelf life of these products by minimizing exposure to air and moisture, which can lead to spoilage. Additionally, the transparent nature of the bags allows consumers to visually assess the quality of the product before purchase, thus enhancing consumer confidence.

Beyond the food sector, heat shrink bags find utility in retail and e-commerce. They are increasingly adopted for bundling multiple products, providing an attractive and organized presentation. The bags can be custom printed with branding and care instructions, effectively serving as both packaging and promotional materials. Furthermore, their lightweight nature contributes to reduced shipping costs, making them a favorable choice for businesses focused on efficiency.

The advantages of heat shrink bags extend beyond their applicability. They offer excellent puncture resistance, ensuring that delicate items remain protected during transport and handling. Their compatibility with automation—such as shrink bundlers—allows for expedited packaging processes, which are crucial in high-demand environments. Moreover, heat shrink bags are available in various sizes, thicknesses, and finishes, allowing companies to choose solutions that best suit their specific needs.

However, as with any packaging method, environmental considerations cannot be overlooked. The production and disposal of heat shrink bags raise concerns regarding plastic waste and sustainability. Efforts are being made within the industry to develop biodegradable alternatives and recycling programs to mitigate these issues. Companies are increasingly prioritizing eco-friendly practices by utilizing materials that are recyclable and promoting circular economy initiatives.

In conclusion, heat shrink bags represent a multifaceted solution in the packaging landscape, offering benefits in protection, presentation, and efficiency. Their widespread use in diverse industries underscores their importance in contemporary packaging practices. As the push for sustainability continues to reshape the packaging industry, the evolution of heat shrink bags will likely involve innovative approaches that balance functionality with environmental responsibility. Through ongoing advancements, heat shrink bags will remain a vital component in meeting the packaging needs of the future.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी