EVA Inserts Injection Molding

Send Inquiry

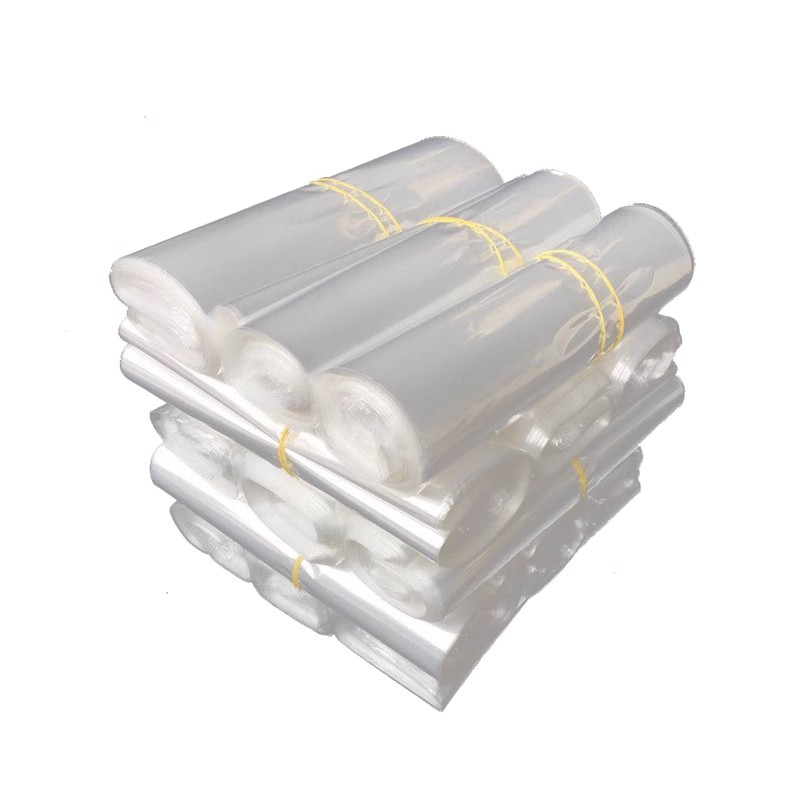

EVA Inserts Injection Molding is a plastic mold used to produce eva lining. eva lining is a material commonly used in shoes, bags and other products, with light, soft, wear-resistant and other characteristics, so it is widely used in the manufacturing industry. In order to produce high-quality eva linings, specially designed injection moulds are required.

EVA Inserts Injection Molding are usually made of metal materials, such as steel or aluminum alloy. These molds have a sophisticated design and manufacturing process to ensure that the eva linings produced meet specifications and quality requirements. The design of injection mold includes mold structure, injection molding system, cooling system and other aspects, which need to consider material flow, temperature control, pressure regulation and other factors to ensure the quality of the final product.

When using the EVA Inserts Injection Molding, the operator needs to strictly abide by the operating procedures to ensure the normal operation of the mold and the production of products that meet the requirements. Regular maintenance and maintenance of the mold is also very important to extend the service life of the mold and maintain stable product quality.

The production process of EVA Inserts Injection Molding includes mold design, manufacturing, debugging and production. Mold design is a key link in the entire production process, and the structure and parameters of the mold need to be determined according to product requirements and production processes. The manufacturing process requires precision processing equipment and technology to ensure the accuracy and quality of the mold. The debugging stage is to test and adjust the mold to ensure that the product meets the requirements.

In general, EVA Inserts Injection Molding play a crucial role in the production of eva lining. Through precise design, manufacturing and operation, high-quality eva lining products can be produced to meet the market demand. With the continuous development of manufacturing technology, the design and manufacturing of EVA Inserts Injection Molding are also constantly innovating, providing more possibilities for industrial development. It is hoped that through continuous efforts and innovation, EVA Inserts Injection Molding can better provide high-quality products for manufacturers and consumers.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी