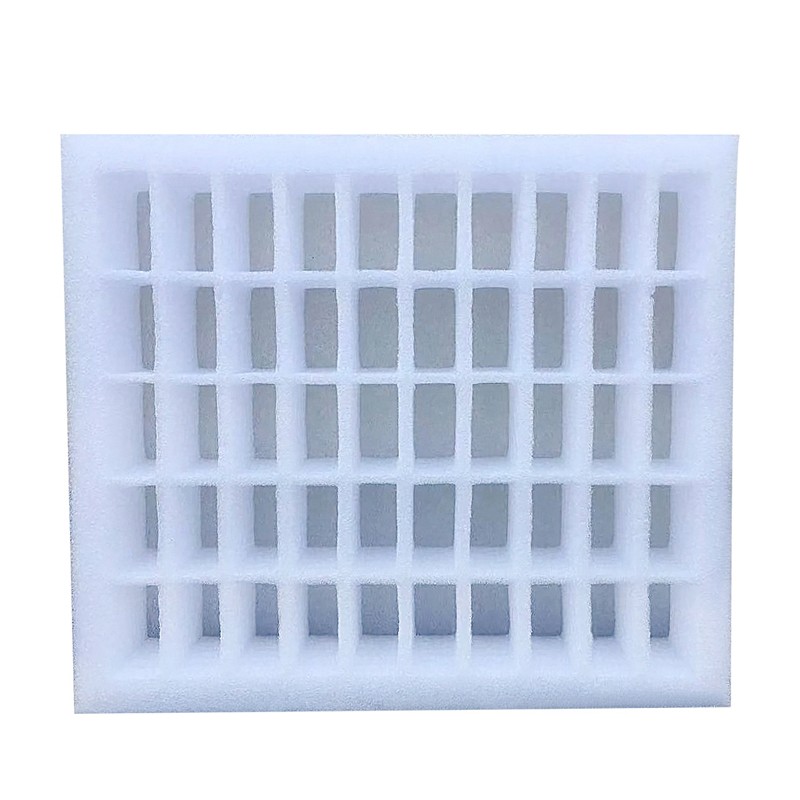

EPE Foam Cushioning

Xiamen Guanhua is a factory with more than 10 years of production experience, the main EPE Foam Cushioning products, product variety, affordable, looking forward to cooperating with you!

Send Inquiry

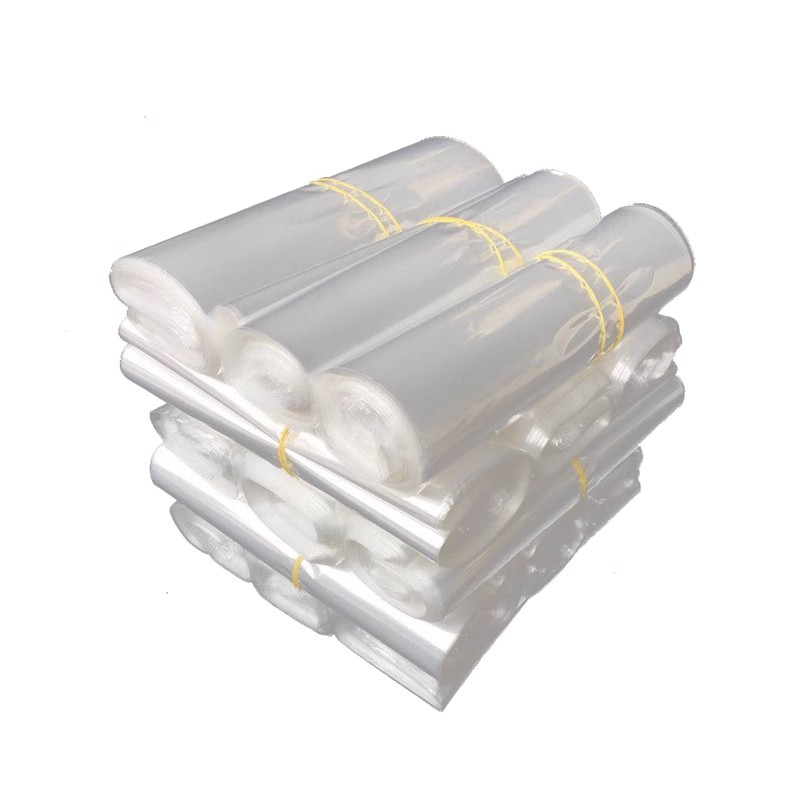

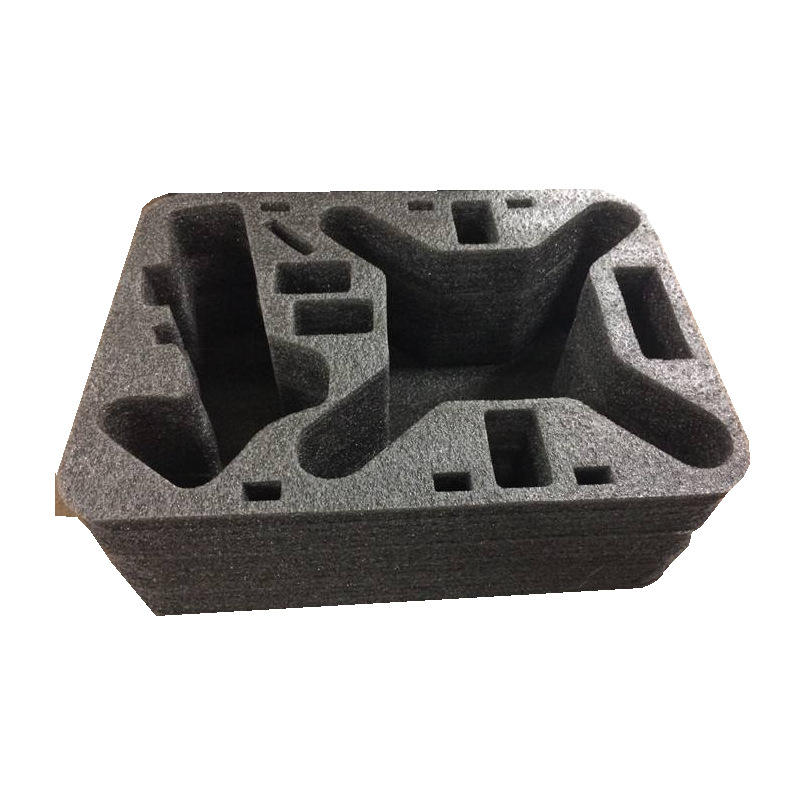

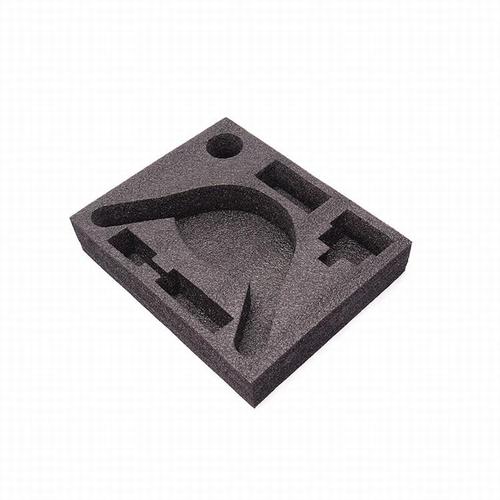

EPE Foam Cushioning material. Polyethylene foam, is a common packaging material used to protect products from damage during transportation and storage. It has the characteristics of lightweight, soft, impact resistance and waterproof, so it is widely used in various industries, such as electronic products, furniture, glassware and other packaging.

EPE Foam Cushioning material is made of polyethylene resin through foaming processing, with closed cell structure, so that it has good buffer performance. It can effectively absorb and disperse the external impact force, and protect the packaging items from damage. In addition, EPE foam also has excellent thermal insulation properties, which can keep the temperature of the product stable during transportation.

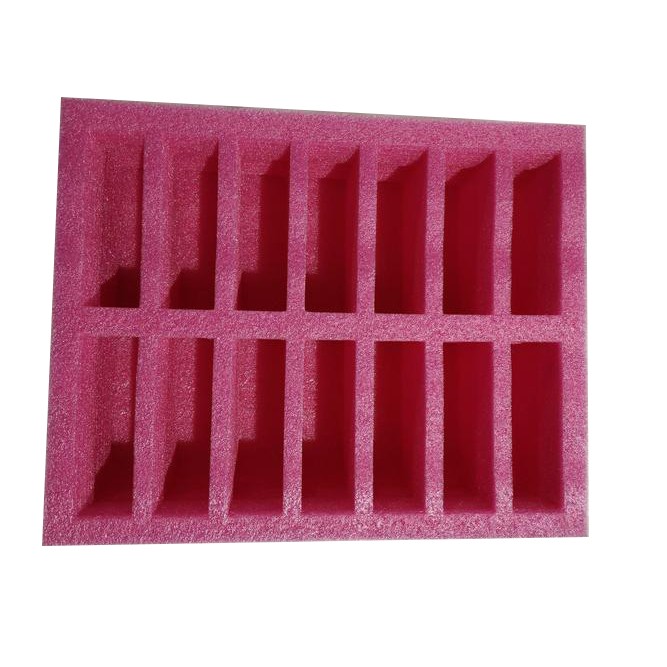

In the packaging industry, EPE Foam Cushioning materials are widely used. It can be made into cushion pads of various shapes and sizes, such as foam board, foam tube, foam Angle, etc., to adapt to the packaging needs of different products. In addition, EPE foam can also be used in combination with other packaging materials, such as cartons, tapes, etc., to improve the protective performance of the overall packaging.

In addition to its application in the packaging industry, EPE Foam Cushioning materials are also widely used in other fields, such as construction, automobiles, sports equipment and so on. In the construction sector, EPE foam can be used as a sound insulation material to reduce noise transmission; In the automotive field, EPE foam can be used as a buffer material for automotive interior parts to improve ride comfort; In the field of sports equipment, EPE foam can be used as a protective mat for fitness equipment to reduce sports injuries.

In general, as an excellent packaging material, EPE Foam Cushioning material has the characteristics of light weight, soft, impact resistance and waterproof, and is widely used in various industries. With the continuous progress of science and technology, the performance and application fields of EPE Foam Cushioning materials will continue to expand, providing a more reliable solution for the packaging and protection of products.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी